Intertronics moves conformal coating ahead of the game

First level defence of electronic assemblies is often a post-assembly dielectric spray used to protect against moisture, bio-hazards and low level mechanical problems. Now Intertronics’ sales partner DYMAX Corp have trialled their Dual-Cure 9481 Conformal Coating, showing significant improvements over previously available products.

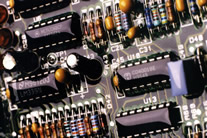

Dual-Cure 9481 is a new coating which represents the latest leap in light/moisture cure technology. Dual-Cure 9481 is specifically formulated to ensure complete cure in coating applications where shadowed areas on high density circuit boards are a concern. Previously, areas shadowed from light were managed by selective coating- eliminating the need to cure in shadowed areas- or a secondary heat cure process. Users needed to balance the cost of selective dispensing equipment and time/energy costs of a secondary heat cure. With Dual-Cure 9481 Conformal Coating, shadowed areas cure over time with moisture, eliminating the need for that second process step or concerns of component life degradation due to temperature exposure. In addition, Dual-Cure 9481 fluoresces bright blue when exposed to UV light and is low viscosity, allowing it to be dispensed easily.

DYMAX has conducted extensive laboratory, as well as field testing of Dual-Cure 9481, which is now available from Intertronics in the UK. The results indicate substantial progress in addressing those challenges typically associated with conventional dual-cure materials. Dual-Cure 9481 is formulated to address high-volume production and field trials have resulted in very favourable response from a variety of pcb assemblers.

Historically, light-cured conformal coatings have been most successful in applications with no or minimal shadowing. Shadow areas, which can inhibit the access of light, have the potential to hold or trap the conformal coating and limit the full cure of the materials. In recent years, several companies have made attempts to commercialise conformal coatings which address the need for shadow curing with conventional moisture curing as a secondary cure mechanism. Most of these attempts have had limits related to the efficiency of the cure as well as the consistency of the final properties. Other challenges have included special packaging and handling requirements as well as objectionable odours – substantially now dealt with in Dual-Cure 9481. Further information regarding Intertronics’ products can be found at www.intertronics.co.uk.

Similar articles

More from Intertronics

- WACKER signs up Intertronics for silicone distribution 18th July 2018

- Automated sealant dispensing proves a winner for golf 26th April 2018

- Large area benchtop dispensing robot 13th April 2018

- Volumetric dosing pump offers high precision rates 1st February 2018

Write a comment

No comments