Control Systems

Displaying 1 - 10 of 770

Ruggedised controls “survive and thrive” in tough environments

Authorised design-in partner Astute Electronics is now offering APEM’s extensive range of ruggedised controls comprising switches, joysticks, indicators, and complete panel solutions.

3rd June 2024

Farnell adds Eaton heft to industrial automation range

Farnell has expanded the range of products it stocks from Eaton, including automation, safety, motor applications, power management and energy solutions for Industry 4.0.

20th July 2023

Logic controllers communicate via Bluetooth

In stock now at distributor Mouser Electronics are Millenium Slim logic controllers from Crouzet.

5th December 2021

Robotics company uses igus product to keep robots alive

An industrial robotics company is continuing to breathe new life into old robots - thanks to a newly designed product from igus. The global manufacturer of energy chain systems and polymer plain bearings, igus, was asked for a control panel cable management system by the team from robotics company, ARAGON.

9th February 2021

New iQ-F extension modules for integrated safety

As automated systems are becoming more extensive, they require corresponding safety controllers to maintain operations. Mitsubishi Electric’s latest iQ-F safety extension modules bring reliability to the next level. These compact, fully integrated units streamline installation and configuration while improving data visualisation and integrity.

14th December 2020

ATOM encoders deliver custom motion control solutions

Partnership with Renishaw makes a significant contribution to the success of JUSTEK Inc. - a motion control component manufacturer based in Korea. JUSTEK has developed a range of customisable Direct-Drive (DD) motors using Renishaw’s high performance optical position encoders, including the miniature ATOM RCDM rotary encoder system, for the FPD and semiconductor/electronics industries.

24th November 2020

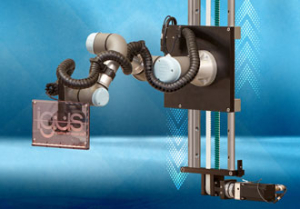

Robot range extended with new 7th axis from igus

A ready-to-fit 7th axis has been designed and manufactured by igus to enable Universal Robots (UR) and robolink robots to travel several metres. The global manufacturer of energy chain systems and polymer plain bearings, which has its UK headquarters in Northampton, has developed this robotic solution to include a maintenance-free, drylin ZLW toothed belt axis, corresponding adapter plate and a switch cabinet, cables and software.

18th November 2020

Steering into the future for mobile machinery

Parker Hannifin has launched a mobile directional control valve that can be used in a Steer-by-Wire system for earth-moving equipment and other types of mobile machinery. This high performance single fault tolerant valve is designed to support the ongoing evolution and trend for electrification of vehicles in this market.

17th November 2020

Control Systems documents

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex