Quiet, strong, easy to fill: E2.1 e-chains tick all the boxes

Energy supply using polymer e-chains are virtually unlimited, whether the application is linear, vertical or rotational. And new polymer materials, improved designs and customer-specific requirements are continually expanding the product range, exemplified by the E2.1, the new e-chain standard for the small and medium load range.

In the 1970s, igus in Cologne was one of the first companies in the world to manufacture polymer energy chains for industrial applications. Back then, the products could be listed on two pages, but the e-chain catalogue now covers over 1,300 pages with 90,000 types of chains from stock, making the igus range the largest selection of energy chains for moving applications in the world.

The range covers products from 3D robotic energy chains and micro-e-chains with the smallest inner heights and bend radii, up to universally applicable all rounder chains as a modular system for assembling individual machine builds.

igus e-chains have developed continuously since those early versions, in both their form and mechanical function, making longer unsupported lengths, more additional loads and longer travels, as well as multi-directional movement possible. Meanwhile, the development of new materials have made igus energy chains lighter and quieter.

Furthermore, applications for energy chains have become more diverse: igus now has special e-chains for use in cleanrooms, the food industry, the wood industry, for offshore, crane systems and agriculture. And with 'smart plastics', the e-chain has even become intelligent with built-in predictive maintenance functions. However, the core idea of developing reliable machine parts that extend the service life of machines and systems while reducing costs remains to this day.

E2.1: igus e-chain standard for small and medium sizes

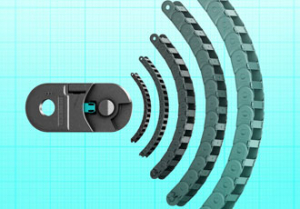

The E2.1 is an all-rounder e-chain for small and medium loads. This new generation of the two-piece energy chains (with chain links and crossbars) was developed to improve on the original E2/000 series, which has proved its worth for over 15 years. The E2.1 series e-chain can be filled very quickly from the side or from the top - along the inner or outer radius, using a chain opener or screwdriver - where one metre of the energy chain can be opened in just two seconds. These features make the E2.1 suitable for use in general engineering, woodworking, metalworking, and in machine tool building.

The E2.1 inner heights range from only 10mm up to 48mm. “Customers can put together the solution that suits them best from over 850 different chain combinations," explained Jörg Ottersbach, Head of the e-chain division at igus. A special design feature of the new E2.1 is the unique 'lens-shaped' brake at the stop-dog of the chain links, ensuring very quiet chain travel with low vibration and noise.

The innovative E2.1 brake design reduces noise by up to 10dB compared with the previous E2/000 chains and the chain series is up to 15dB quieter than comparable energy chains on the market. This was proven by tests at 2m/s in an insulated sound chamber at the 2,750m2 igus test laboratory.

Customised energy supply thanks to maximum flexibility

The E2.1 also has an optimised interior, offering more space with the same outer height when compared to the E2/000. For cable separation, igus offers a complete range of lean separators with rounded edges, ensuring long service life of hoses and cables even with long travels. Assembly of the interior separation with lean separators is up to 50% faster than previous solutions, ensuring faster harnessing.

For side-mounted applications there are notch separators that engage in a narrow, integrated grid in the crossbar and guarantee a secure fit. Also it is very easy to insert shelves on several levels for multi-layer separation.

The opening mechanism of the crossbars along the inner and outer radii is simple, allowing fast filling with cables and hoses. These captive crossbars can be pivoted open to 115 degrees and latched into their final position or they can be removed completely, fitted again and closed by just pressing down. The rounded edges of the crossbars and separators of the chain also ensure a long service life of hoses and cables, reducing wear. Notches and a positioning scale enable optimum separation of the energy chain. With matching and highly flexible chainflex cables and connectors, the E2.1 is available as a complete, ready-to-connect energy solution called 'readychain', saving machine builders valuable time.

QR code explains assembly instructions easily

A built-in QR code on the E2.1 connects quickly to the internet, allowing access to more information, easier assembly and direct spare part procurement. Scan the QR-code with a smart phone or tablet camera, and get directed to an online portal with all the important product information, including photos and videos that show the assembly instructions.

Important assembly steps are shown in slow motion for better understanding. This QR-code feature helps reduce set-up times and simplifies initial installation, and also simplifies the process for ordering spare parts. Intuitive illustrations on the website help the user to understand the structure of the igus part numbers and to recognise different components. The online shop is just a click away, where an order can be placed, and components are dispatched for delivery from 24 to 48 hours later.

Quickly openable and tightly sealed: swarf-repellent e-tubes from igus

In addition to the E2.1 product range, these e-chains are also available as enclosed energy tubes in the R2.1 range, which has the same design features as the E2.1. The swarf-resistant, stable e-tubes are available in 26, 40, 48 and 75mm inner heights and are mainly relevant to the machine tool industry where a reliable energy supply is often required in the swarf area.

The machine-tool industry is faced with the enormous challenge of mastering rising input prices combined with rapidly growing technical requirements for parts. During the swarf test, it was shown that the tubes of the R2.1 series are among the tightest sealed energy tubes on the market. During one of the lab tests, the tube is moved continuously in a swarf drum filled with two kilograms of metal swarf of different sizes and shapes. After 100,000 cycles, the size 40 e-tube R2.1 allowed only 0.5 grams of swarf to accumulate inside.

Similar articles

More from igus UK Limited

- From garage business to world leader: igus founders celebrate 90th birthday 22nd June 2021

- VOTW - Metal out plastic in! 10th June 2021

- igus robot works alongside agri-tech startup 18th May 2021

- Tribo-polymers increase machine service life and efficiency 10th May 2021

Write a comment

No comments