HARTING offers solutions for interfacing power to printed circuit boards

HARTING Integrated Solutions has extended its design and manufacturing capabilities for applications requiring PCBs capable of transmitting high-power using a range of solutions designed to connect high currents directly onto the PCB.

In addition to their normal use for carrying data and signals, backplanes and passive PCBs are used to link the power supply to connected devices. In order to handle the necessary current levels, HARTING Integrated Solutions uses a range of connectors that offer advantages for different applications and designs.

The HARTING Han connector family includes PCB adapters from the Han modular portfolio that can supply currents to the PCB from 7.5 A to 40 A. When combined with HARTING Integrated Solutions' expertise in mechanical integration, this approach can save space and assembly costs when interfacing with I/O connections.

The Han-Fast Lock connector allows even higher currents of up to 60 A, and simply needs to be inserted into a plated hole provided for the contact which is locked in place with an integral latching pin and can be released again if necessary.

Another connector in the HARTING range, the compact har-flexicon connector, is rated for currents from 6 A to 17 A and is available in pitches of 1.27 mm, 2.54 mm, 3.50 mm/3.81 mm and 5.00 mm/5.08 mm. It is suitable for processing with reflow soldering, and offers both field-installable screwless push-in spring force and insulation displacement termination technologies for single-strand wiring.

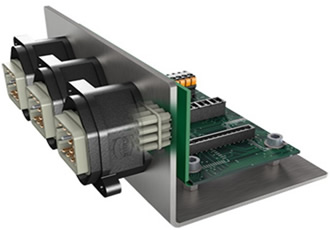

HARTING can also supply ‘classic’ connector types for the combined transfer of signals and power. The DIN Power connector can transfer up to 40 A together with signal and data in one standard DIN 41612 connector. The HARTING D-Sub Mixed connector allows a current of up to 40 A in an industry standard I/O connector along with a range of other high-current, high-voltage, coaxial and pneumatic contacts in addition to standard signal contacts.

High currents routed in proximity to sensitive PCB signal paths can present challenges in terms of PCB design and thermal management, and HARTING Integrated Solutions offers the expertise to overcome these issues by developing custom backplanes and passive PCBs.

The company, part of the HARTING Technology Group, is active at three locations in Asia, Europe and the USA and specialises in designing, prototyping and manufacturing PCBs in made-to-order batches or low to medium volume production.

Similar articles

More from HARTING Limited

- Digital condition monitoring system for overhead conveyors 15th March 2019

- Connectivity solutions designed to help the IIoT world 20th February 2019

- Machine predictive maintenance improves pharmaceutical productivity 1st May 2018

- Efficiency improvements based on Integrated Industry 4.0 and IoT 12th February 2018

Write a comment

No comments