Air logic from Parker offers simple alternative to PLCs

7th July 2010

Source:

Parker Hannifin

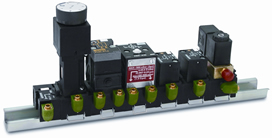

The latest range of air logic devices, developed and manufactured by Parker Hannifin, now offers engineers an extremely efficient and cost effective modular system that can improve productivity, reliability and profitability of pneumatic circuits in a wide range of applications. In particular, the latest air logic devices can be used as an alternative to conventional PLCs, for managing smaller or less complex pneumatic circuits, and in areas where there is no electrical supply or where compliance is required with ATEX directives.

Parker’s air logic system comprises a series of compact modules that operate in response to the condition of inlet and exhaust signals from connected upstream pneumatic devices, effectively replicating the operation of electrical switches and relays. They can thus be used individually or combined in series to create a range of simple or advanced functions.

For example, when used as individual in-line modules they can provide passive AND/OR functions. Alternatively, modules can be grouped together and mounted on standard rails, on sub-bases with a common air supply or in cabinets to provide active AND, OR, NOT, YES and MEMORY functions, with functionality being extended still further through user selectable cascade or common input modes.

Modules are designed to plug together quickly and simply, with all inlet and exhaust connections being front mounted, and can easily be reconfigured if the requirements of the application change. For rail or sub-base mounted systems this makes it possible to halve the amount of piping that would otherwise be needed. Operating pressures can be between 3 and 8 bar, at temperatures from -40ºC to +60ºC, with modules typically having a response time under 3msecs and an operating life greater than 10million cycles at pressures of 6bar.

Parker’s latest air logic system is lubrication-free, incorporates pressure test points as standard, and is available with a range of accessories. These include time delays, bleed sensors, solenoid actuators, pressure switch relays and modular sequencers. The latter are designed to provide an easy to use method of controlling machines that need to go through a defined set of cycles.

Parker’s European Product Manager for Air Logic, Claude Barrabès, explains that, “The strength of our air logic products lays in their ability to provide an extremely reliable and efficient method of configuring and controlling pneumatic circuits in applications where an electrical supply is unavailable or where ATEX controls apply; typically, these include the chemical, mining, transport and offshore sectors. Just as importantly, Parker air logic can be used in equipment such as robotic welders, where high electromagnetic fields can adversely affect electromechanical devices, and also offers a cost effective alternative to PLC controlled systems, where our products are far simpler to set up and operate without the need for specialised programming knowledge.”

Similar articles

More from Parker Hannifin

- Flange system gains new certification for marine applications 4th June 2021

- New generation of oil condition monitoring technology 2nd June 2021

- Parker introduces new low GWP refrigeration dryer series 24th November 2020

- Steering into the future for mobile machinery 17th November 2020

Write a comment

No comments