HepcoMotion

Address:

LowerMoor Business Park

Tiverton Way

Tiverton

Devon

EX16 6TG

United Kingdom

Tiverton Way

Tiverton

Devon

EX16 6TG

United Kingdom

HepcoMotion articles

Displaying 21 - 40 of 46

FIT AND FORGET RING SYSTEM CHOSEN FOR SMOOTH RUNNING

The skill of Paragon Creative is in designing and manufacturing display products that are able to withstand frequent use - and sometimes abuse - by the public. Based in York, the company prides itself on providing a comprehensive range of creative and practical skills under one roof. It makes models, designs and builds interactives, murals, props & prototypes and animates the inanimate. Naturally the markets for its products are diverse but a recent project for a major cruise ship company is a good example of its craftsmanship.

24th May 2010

HEPCOMOTION COMMITMENT TO CONTINUOUS IMPROVEMENT

Linear motion specialist HepcoMotion® is implementing proven business tools and techniques for lean manufacturing and the initiative is already paying dividends. In just eight months, results can be measured in a reduction of lead times, improved quality, generation of less waste material and greater operational efficiency.

22nd March 2010

HepcoMotion: DEDICATED LINEAR ACTUATOR FOR EACH AXIS

X-Y-Z linear motion systems, they are widely used throughout industry but demands on the various axes vary considerably. Linear motion specialists, HepcoMotion®, have therefore developed a family of actuators to address these different needs so that each axis operates optimally and contributes to the overall efficiency and longevity of the system.

23rd February 2010

STANDARD AUTOMATION COMPONENTS ACHIEVE MICRON POSITIONING ACCURACY

A new, fully automated, fine art infrared scanning system isn’t just a prime example of what modern technology can achieve. It also shows how a scientific tool with micron positioning accuracy can be created from standard industrial automation components. The system is the brainchild of motion control specialist, SmartDrive®. Working in league with the linear motion company, HepcoMotion®, it has optimised the process of infrared scanning, greatly extending the scope of the technology. And the benefits of the system aren’t confined to infrared. The system control and specifically developed image stitching software also enables distortion-free digital photographs of large works to be taken for further study and record. For the art conservation world this system represents a significant imaging breakthrough.

16th February 2010

Machine Building & Automation exhibition: HepcoMotion stand no: 1630

Machine Building & Automation - 27TH & 28TH April 2010, NEC

HepcoMotion stand no. 1630

The notion that any type of linear actuator can be chosen for any axis in an X-Y-Z system will be challenged by HepcoMotion® at this year’s Machine Building Show. The demands on each of the axes vary considerably so a ‘one-type-fits-all’ approach will ultimately compromise performance, reliability and service life of the overall system.

1st February 2010

APPRENTICES MAKE SOUND BUSINESS SENSE FOR HEPCOMOTION

With unemployment figures rising and the future looking bleak for those wanting to break into the engineering industry, HepcoMotion has pledged to strengthen its commitment to recruiting apprentices.

21st December 2009

REGIONAL RECOGNITION FOR HepcoMotion APPRENTICE

The accolades just keep coming for HepcoMotion engineer, Katie Webber. The 24-year old has just been named runner-up in the South West finals of the Engineering Employers Federation (EEF) Future Manufacturing Awards. Katie learned of her achievement at the Awards ceremony on board SS Great Britain in Bristol on Wednesday 18th November 2009.

21st December 2009

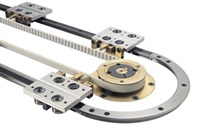

Linear motion rings up to 8m and beyond

Linear motion specialist, HepcoMotion, is world-renowned for its prowess in the field of circular and continuous motion. It is also unique in its ability to produce rings with diameters from .1m to 8m, or even larger. Indeed it has perfected the art of manufacturing ring segments to ensure both concentricity and smooth running of the finished product, whatever its diameter. So ring systems greater than 8m in diameter are eminently feasible.

17th November 2009

Extensive wheel choice now includes sun-zero

HepcoMotion designs and manufactures linear motion systems to suit every type of automation environment and this ability is complemented by a similar diversity in its DualVee Motion Technology™ range from BishopWisecarver. With the introduction of low temperature DualVee wheels, now available in the UK from HepcoMotion, the application scope for this established product programme has been significantly enhanced. DualVee systems can now be specified for automation systems in aerospace, refrigeration and other sub-zero climates.

20th October 2009

PSD80 - Exceptionally versatile screw driven linear actuator

The wide range of screw options available with the new PSD80 screw driven linear actuator is one of the reasons why it is so versatile. A high lead model for example allows direct coupling of a stepper motor providing a particularly cost effective solution. The unit can also be specified with opposing left and right hand carriages as a “double acting” version. As a result the application scope of this newcomer ranges from light pick and place and assembly operations involving XYZ movements to instrument positioning systems. And in “double acting” format it is ideal as a specialised door and shutter opening and closing mechanism.

18th September 2009

Rotary table replaces inaccurate linear moving table

In the continuous flow manufacture of its lighting products Whitecroft Lighting Ltd employs many automated systems one of which is a robot for automatic direct wiring of standard components. Installed twelve years ago, this robot received a new wiring head and software in 2006. And last year it was fitted with a new rotary table, supplied by HepcoMotion®, the benefit of which has been connection accuracy of 99%.

18th August 2009

OFFSHORE EUROPE 2009 – HepcoMotion stand no: 601

The reasons why HepcoMotion is so widely specified for marine and offshore engineering projects will be clearly demonstrated on the company’s stand at Offshore Europe ‘09. Stainless steel and corrosion resistant linear motion systems, a new heavy duty addition, proven circular and continuous motion products and the ability to design and manufacture complete sub-systems continue to give HepcoMotion the edge in this demanding sector.

13th July 2009

New look website launched

HepcoMotion has an exceptionally wide range of products to cater for every linear motion need. That presents any website designer with a challenge. It is no easy task creating a framework that is both clean and easy to navigate whilst accommodating comprehensive information on so many products. Nevertheless, that is exactly what has been achieved in the new HepcoMotion website.

8th July 2009

Long life wheels for washdown environments

The life of a bearing, within linear systems, can be seriously compromised in a harsh, washdown environment due to the ingress of corrosive fluids and loss of lubrication and this is precisely the reason why DualVee Washdown Wheels have been developed. Available from HepcoMotion these wheels actively repel liquid making them ideally suited for food and beverage applications as well as any high speed waterjet cutting application.

23rd June 2009

Lean manufacturing drastically cuts ring slide lead time

As well as the continual development of its products HepcoMotion is also committed to the continual development of its manufacturing processes. And with this as the motive the Tiverton-based company has recently taken advantage of a programme offered by the South West Manufacturing Advisory Service. The result has been the introduction of lean manufacturing techniques that have given rise to important benefits for ring slide customers.

13th May 2009

GV3 the ideal choice for tough environments

Robust build quality to withstand hostile environments is a standard feature of the GV3 linear motion system from HepcoMotion®. Its all steel slideway is three times stiffer than composite aluminium systems. And continuously developed for more than fifty years, the ‘V’ concept is also central to GV3’s superior performance in tough conditions.

17th February 2009

HepcoMotion Driven Linear System helps minimise aircraft noise

With the economic and social benefits of air travel comes increased responsibility for minimising environmental impact and that is the purpose of a newly refurbished laboratory at the Institute of Sound and Vibration Research (ISVR) at the University of Southampton. The facility is housed on campus in the Rolls Royce University Technology Centre in Gas Turbine Noise. It is an anechoic chamber in which detailed measurement and analysis of the noise emission from Rolls Royce aero engine components is now being undertaken. The results will help researchers understand how and why these components generate noise with the ultimate aim of developing noise reduction technologies.

23rd December 2008

SOUTHERN MANUFACTURING 2009 - Stand No. K30

Automating a process can make a big difference to the cost of the end product. Done correctly it can boost productivity, improve quality and help ensure profitability. However not all manufacturers have the skill or the time to engineer their own automation systems. So it is for customers such as these that linear motion specialist, HepcoMotion®, provides a complete systems design and manufacturing service.

18th December 2008

MACHINE BUILDING & AUTOMATION 2009 - HepcoMotion stand number - 1010

Easy automation is the main focus of the HepcoMotion® stand at Machine Building 2009. A world renowned specialist in linear motion technology, this British company is also carving out a niche for itself as a designer and manufacturer of complete linear systems. All the customer has to do is provide an outline specification. HepcoMotion® will then design it on 3D CAD, accommodate any modifications that need to be made, assemble and thoroughly test the system before despatching it for integration. This eliminates risk for the specifier as HepcoMotion® has the expertise and manufacturing capability to create a system that is fully fit for purpose.

18th December 2008

Anti-friction linear guidance literature

In common with all products in the HepcoMotion® linear motion range the Bishop- Wisecarver (DMT) DualVee Motion Technology® single edge slide system is also subject to continuous development. Thanks to new bearing design and tighter manufacturing tolerance the wheel capacity on this system is now increased by 40%. The range also has several new wheel and track options to save installation time and costs.

20th November 2008

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex