Machining

Displaying 1 - 10 of 460

Flange system gains new certification for marine applications

Parker Hannifin has announced that its mechanical flange system for machines and plants (with working pressures of up to 420 bar) - “HPF - Parker High Performance Flange System” - has gained DNV GL approval for marine applications. The DGUV approval certifies the use of Parker’s HPF in hydraulic systems for injection moulding machinery as well as in hydraulic and mechanical presses.

4th June 2021

Sandvik launches an innovative smart packaging solution

Sandvik Coromant is launching an optimised smart packaging solution to level up its operational sustainability. Developed by R&D engineer and system developer, Maria Rajabzadeh Namaghi as part of Sandvik Coromant’s Automation Platform team, the solution uses Artificial Intelligence (AI) to determine the smallest possible packaging required to contain a product, reducing costs and CO2 emissions in the process.

2nd June 2021

Tribo-polymers increase machine service life and efficiency

Assessing the service life of a machine must take account of the costs of purchase, procurement and installation, as well as all the costs incurred in the long term operation, maintenance and repair of the machine. Using wear-resistant materials and low-maintenance components reduces not only running costs but also the risk of unscheduled shutdowns and extensive maintenance work.

10th May 2021

Composite components: advancing automated machinery

In an athletic sprint race, a split second can mean the difference between winning and losing. It’s been shown that athletes who sprint 40 meters wearing spiked shoes can finish 0.11 seconds faster than those wearing jogging shoes. Just like in athletics, using the right components in automated machinery can have a significant impact on performance. Here, Robert Glass, Head of Marketing at Exel Composites, explores how using composite components can enhance automated production lines.

20th April 2021

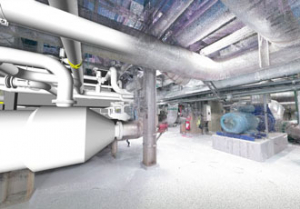

3D paves the way to a safer plant

Umeå Energi can now focus on the critical points in the pipe system at the heating plant in Ålidhem, Sweden. FVB has conducted 3D scanning, 3D modelling, and expansion calculation at the plant to get the facts. “We’ll now have a better and safer plant,” said Konny Lindberg, who is in charge of plant development at Ålidhem’s heating plant.

7th April 2021

Combining user-friendliness with high performance

Mitsubishi Electric has helped JK Machinery Ltd upgrade the design of an automated printing machine to deliver an enhanced, futureproof and cost-effective solution to its customers. The new unit, which is now the company’s flagship, offers next-level performance enabled by Mitsubishi Electric’s advanced automation products. These include the latest FR-A800-R2R Variable Speed Drive (VSD) with dedicated winding functions, MELSERVO-J4 servos, a MELSEC iQ-F series PLC with simple motion module and a GOT2000 series HMI.

16th March 2021

3D printed grippers transform packaging machine

Animals and birds can adjust the power and position of their grip in many ways to suit their needs. Industrial applications tend to be binary in comparison; mechanical grippers used for attaching lids to jars, for example, have very restricted, 'closed/open' dexterity. When a new product is introduced, a new gripper to match that product can take weeks to design and manufacture.

16th March 2021

The benefits of using composite components in machinery

Cheetahs are famed for their ability to reach high speeds, but it is in fact their agility that is truly impressive. Cheetahs can accelerate from zero to 60 miles per hour in just three seconds, and then quickly decelerate, turn, and sprint in another direction. But this exceptional combination of speed and precision doesn’t purely belong to the wild, and innovative composite materials are helping bring these qualities to the factory floor. Here, Robert Glass, Head of Marketing at Exel Composites, explores how composite components can enhance the performance of automated machinery.

15th March 2021

New long-life coating for food machinery

Sheet metal and metallic parts in food processing are regularly exposed to friction and wear. igus has developed a new coating material to increase the service life of these components, by reducing friction and wear. The IC-05 tribo-polymer protects sensitive and small bearing points as well as sliding surfaces, it is coloured blue for high visibility and is approved for use in manufacturing by the Food & Drug Administration (FDA).

4th March 2021

Elastic double joint proves a quiet solution for labelling machines

A new elastic double joint from igus is proving to be a perfect - and quiet - solution for the machine building sector. The igubal GPZM coupling joint, which was officially launched at the end of 2020, is lubrication-free, maintenance-free and 20% more flexible than its conventional alternative.

23rd February 2021

Machining documents

Product Centre Updates

2024 World Battery & Energy Storage Industry Expo (WBE)

8th August 2024

China 1st and 2nd Floor, Area A, China Import and Export Fair Complex

ed.jpg)

ED.jpg)