SOUTHERN MANUFACTURING 2009 - Stand No. K30

18th December 2008

Source:

HepcoMotion

Automating a process can make a big difference to the cost of the end product. Done correctly it can boost productivity, improve quality and help ensure profitability. However not all manufacturers have the skill or the time to engineer their own automation systems. So it is for customers such as these that linear motion specialist, HepcoMotion®, provides a complete systems design and manufacturing service.

On its stand at Southern Manufacturing the company will emphasise its expertise in this field and demonstrate some of the many driven linear systems that complete its standard range.

System design is an increasingly important part of the HepcoMotion® business. All the customer needs to do is provide an outlined specification and HepcoMotion® will do the rest. It designs the system on 3D CAD, submits it to the customer for approval and incorporates any subsequent modifications. The agreed system is then built and thoroughly tested at the HepcoMotion® factory in Tiverton, Devon.

For the customer who requires a stand alone unit either belt, screw or pneumatically operated, the HepcoMotion® driven range covers all applications from low to high load and slow to fast speed. Where exceptional positioning accuracy is a pre-requisite its ballscrew drives are the recommended option. If the application is in an aggressive environment or where hygiene is paramount, corrosion resistant and stainless steel products are available. Unusually these are both choices within the standard range, they are not costly specials.

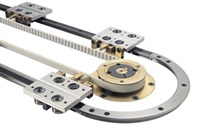

Complementing these elements are HepcoMotion® continuous motion products. They provide low frictional movement for a multitude of tasks and are especially useful where space is at a premium. Complete systems are available with the drive and machine base as in the DTS Driven Track System or as a ring and track system with assembled carriages, the drive then being incorporated within the machine design.

In addition to the mechanical guidance elements, HepcoMotion® systems include all the necessary fixing plates and machine framework that can be either supplied completely assembled or in kit form, ready for reassembly on site. Systems range from simple single axis to multi-motion configurations but typically provide x, y and z lifting motion. To complete the package HepcoMotion® also offers a wide choice of motors and control options.

SOUTHERN MANUFACTURING 2009 - Stand No. K30

11-12 February 2009, Farnborough, Hampshire

System design is an increasingly important part of the HepcoMotion® business. All the customer needs to do is provide an outlined specification and HepcoMotion® will do the rest. It designs the system on 3D CAD, submits it to the customer for approval and incorporates any subsequent modifications. The agreed system is then built and thoroughly tested at the HepcoMotion® factory in Tiverton, Devon.

For the customer who requires a stand alone unit either belt, screw or pneumatically operated, the HepcoMotion® driven range covers all applications from low to high load and slow to fast speed. Where exceptional positioning accuracy is a pre-requisite its ballscrew drives are the recommended option. If the application is in an aggressive environment or where hygiene is paramount, corrosion resistant and stainless steel products are available. Unusually these are both choices within the standard range, they are not costly specials.

Complementing these elements are HepcoMotion® continuous motion products. They provide low frictional movement for a multitude of tasks and are especially useful where space is at a premium. Complete systems are available with the drive and machine base as in the DTS Driven Track System or as a ring and track system with assembled carriages, the drive then being incorporated within the machine design.

In addition to the mechanical guidance elements, HepcoMotion® systems include all the necessary fixing plates and machine framework that can be either supplied completely assembled or in kit form, ready for reassembly on site. Systems range from simple single axis to multi-motion configurations but typically provide x, y and z lifting motion. To complete the package HepcoMotion® also offers a wide choice of motors and control options.

SOUTHERN MANUFACTURING 2009 - Stand No. K30

11-12 February 2009, Farnborough, Hampshire

Similar articles

More from HepcoMotion

- The Ultimate Flexibility In Workbench And Storage System Design 2nd April 2013

- Linear Motion Carriages For High Offset Loads 28th August 2012

- NEW RANGE OF TIMING BELT RING SLIDES, PULLEYS AND BELTS 21st December 2011

- Linear product for innovative packaging machinery 13th December 2011

.jpg)

Write a comment

No comments