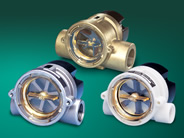

RotorFlow Sensors Combine Continuous Fluid Flow Sensing with Visual Indication

4th August 2010

Source:

Gems Sensors & Controls

Gems Sensors & Controls, introduces the RFO type of the RotorFlow Series of fluid flow sensors. RFO stands for “RotorFlow Output”, and is designed for flow rate monitoring or metering applications. RotorFlow RFO type sensors provide a pulsed DC voltage output that is proportional to the rate of flow. The 4.5 to 24VDC pulsed output is easily integrated into most digital logic units. What makes RotorFlow sensors unique is the highly visible paddlewheel that provides verification at a glance to confirm that fluids are moving. Typical applications for RotorFlow RFO type sensors include water purification, dispensing systems, chemical metering, laser and welders, semiconductor processing, water injection systems, and chillers and heat exchangers.

As liquid passes through the RotorFlow RFO body, a magnetic rotor spins at a rate proportional to flow. The magnetic fields turning with the rotor excite a static Hall Effect sensor, located in the body, and generate a series of voltage pulses. The output pulse voltage is equivalent to input (4.5 - 24 VDC), with a frequency proportional to the flow rate. Digital rate meters, totalizers, and other electronic controllers then utilize the output signal. A subset of the RFO type RotorFlow sensors is the RFA Type. These use the same operating principle, but instead of outputting a voltage pulse they are conditioned to provide an analog output signal of 0-10 VDC.

RotorFlow sensors are offered in ¼” to 1” port sizes, and monitor fluids with flow rates ranging from 0.4 LPM to 227 LPM (0.1 GPM to 60 GPM). Accuracy is dependent on model and flow range selected, and is typically within ±7%. RotorFlow sensors combine their high visibility rotors with solid-state electronics that are packaged into compact, panel mountable housings. Housing bodies are available in brass, stainless steel or polypropylene. Brass and SS bodies provide operating pressures (@ 21°C) to 200 13.8 bar, while polypropylene allows 6.9 bar. Maximum media temperature for polypropylene models is 82°C and with brass or SS bodies is 100°C.

RotorFlow sensors are offered in ¼” to 1” port sizes, and monitor fluids with flow rates ranging from 0.4 LPM to 227 LPM (0.1 GPM to 60 GPM). Accuracy is dependent on model and flow range selected, and is typically within ±7%. RotorFlow sensors combine their high visibility rotors with solid-state electronics that are packaged into compact, panel mountable housings. Housing bodies are available in brass, stainless steel or polypropylene. Brass and SS bodies provide operating pressures (@ 21°C) to 200 13.8 bar, while polypropylene allows 6.9 bar. Maximum media temperature for polypropylene models is 82°C and with brass or SS bodies is 100°C.

Similar articles

More from Gems Sensors & Controls

- New Subminiature, Piston Actuated Pressure Switch 23rd June 2015

- High-Reliability Explosion Proof Pressure Transmitters with Switching Output Capabilities for Hazardous Area Environments 25th March 2015

- Visual Indication, Continuous Sensing and Accurate Switching 17th March 2015

- Intrinsically Safe Pressure Monitoring 21st March 2013

Write a comment

No comments