Fifth wheels delivering reliability and safety for chilled haulier

Because a breakdown or fault during a delivery could happen at any time, operating to the strictest of standards is essential for Hauliers that specialise in temperature controlled haulage for food products. As such, they must work hard to develop strong relationships with high quality suppliers for the components on all of its vehicles.

This importance of these relationships is well illustrated by JOST UK, which supports many specialist companies. Paul Clayton, UK and Regional Technical Sales and Support Manager for JOST UK explained: “It is not enough for us to be suppliers; we have to engage fully and become true business partners. The quality of our products is excellent, and - very importantly - the level of service and back up has to be first class. Hauliers have to be comfortable in the knowledge that they can rely on us.”

As an example of this, Paul recalled an occasion last year, when the fifth wheel on one of a client’s articulated trucks stopped working at the end of a trip. JOST visited the site first thing next day, completed an inspection and identified that the wheel had been damaged through mishandling. “Many companies would have offered to repair it, and inevitably it would have meant the truck being off the road for a couple of days. But our guys had the foresight to bring a spare wheel in the boot of their car and fitted it on the spot.”

Many temperature controlled haulage companies are part of large international groups that specialises in food logistics, and their trucks will often, for instance, take loads right across Europe. Similarly, JOST UK is part of JOST International, so is well able to support companies with hundreds or thousands of vehicle and depots in dozens of countries.

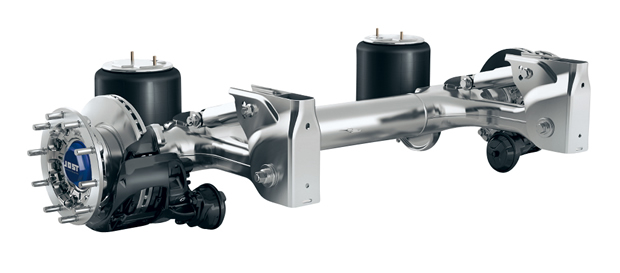

Further JOST is able to supply the full range of equipment for the underside of vehicles, from axles, through fifth wheels, and landing gears, to hydraulics and in-cab controls. Large fleet operators increasing like to source all such equipment from a single supplier so that is one point of contact, which takes total responsibility for all technical matters.

This is particularly appreciated in the world of food transportation, where key design and performance requirements for vehicles include road holding, strength, stability, low maintenance costs, capacity for efficient loading and unloading and efficient service and maintenance back-up.

Other JOST group companies include Rockinginer, Tridec and Edbro.

Clayton continued: “All of the products in the JOST Group family are designed to deliver premium performance. For example our telescopic landing legs offer a performance advantage in that there is no external gearbox. The gearing mechanism is an integral part of the sturdy leg column, which protects the gearing from abuse and, most importantly, minimises water intrusion. “When it comes to axles we can supply full axles and suspensions systems, plus brakes, hubs, callipers, pads, air bags and everything else.”

As the coupling that connects an articulated vehicle’s tractor and trailer, it is essential that the fifth wheel is safe, secure and reliable; while for operational efficiency it must also be easy to engage and disengage. Unsurprisingly there are many safety standards that fifth wheels must meet. They are expected to work in extreme temperatures, endure dust and dirt, rain and snow, and regular impacts from flying stones and roadside debris.

JOST has been manufacturing fifth wheels for over 60 years, during which time it has supplied over three million units to the global market. Its designs are the result of constant development and advanced technologies, particularly in relation to the safety of the locking mechanism and to minimising lifetime ownership costs. Similarly JOST kingpins have proven themselves mile after mile over the world’s most challenging roads. Steel-forged for strength, they deliver optimal balance between wear and impact resistance. They are available in cruciform (AAR) and mushroom (SAE) styles.

Clayton concluded: “Our food industry clients’ tractors and trailers typically do up to 200,000km in their working life and the JOST equipment is designed to perform reliably throughout this time.”

Similar articles

More from Jost UK Limited

- What does the future look like for self-driving trucks? 17th June 2020

- Big order for hydraulic tipper systems 9th October 2019

- MAN tipper trucks warranty includes EDBRO hydraulics 16th August 2019

- JOST’s double display ensured Tip-Ex success 15th August 2019

-(1)ed.jpg)

Write a comment

No comments