You can’t have your beam and shrink it

Efficient and innovative solutions are required from the pressures of the construction industry, to meet construction deadlines and provide a modern, desirable finished structure. Reducing the overall weight of structures has been a large part of this continued innovation, with the structural beam an element that has been pushed to the forefront of this revolution.

Greg North, Commercial Director at Barnshaws Section Benders, explores how weight reduction in beams can be achieved and the benefits this can provide to the design and construction process.

Structural steel has become the default standard for producing low weight and space efficient structures. Steel inherently displays a high weight to strength ratio – which makes it a perfect selection for constructing structural frameworks. It is also incredibly ductile, allowing structural steel beams to be cambered or modified to suit certain structural properties and design aesthetics. Steel can be specified in a range of strengths for certain applications, with fabricators able to refer to regulatory standards to specify the applicable grade for a structure.

For designers, the high strength and low weight of steel allows more spacious buildings, as larger spans can be attained across the structure. This maximises space and consequently the profitability of the building in the long term. Greater strength and increased spans reduce the complexity of design for the structure also, as they require less foundation work and support systems to create a durable framework. Reducing the number of required support systems also contributes additional weight loss across the building.

In flooring applications, steels can be utilised to minimise floor depth, increasing the vertical space efficiency of the building, which in taller buildings can mean extra floors can be incorporated into the structure. From a space efficiency and aesthetic standpoint, steel makes sense.

Besides the inherent benefits of utilising steel as a construction material, further fabrication can be conducted on beams to reduce weight.

Positively cambering a supporting steel beam offers a wide range of advantages. Firstly, the camber serves to deflect the weight of the floors above more effectively throughout the building. This means a smaller cambered beam can be utilised to support the same load as a larger straight section, which dramatically decreases the weight of the overall steel framework. Cambered beams are usually cold rolled or pressed to create the bend, so utilising a metal bending expert such as Barnshaws can mean an optimum weight saving solution dependent on the load demands of the application.

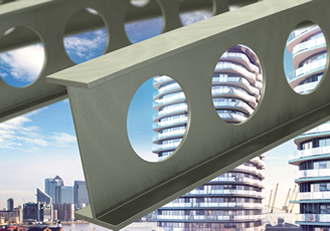

Cellular beams make a great selection for further structural weight reductions. They feature a number of apertures or ‘cells’ incorporated into the section, with the frequency of these cells depending on the design. These cells reduce the weight of the overall section, while also allowing pipes and other services to pass through the section, maximising space efficiency. Floor depth is minimised by utilising cellular beams as services do not have to pass over or under the beam, but rather straight through it.

Increased depth and strength can also be achieved compared to traditional steel sections of the same weight. The increase in depth takes place in the web (the vertical area between the flanges) of the beam, where the addition of cells can increase depth of the section by over 50% compared to a solid web beam of the same weight. The increased depth of the web serves to increase the span of the beam, due to its increased load bearing properties. Usually cellular beams are constructed from welding two profiled tees together, so a lighter top tee can be coupled with a heavier bottom tee to achieve the desired load bearing capability, which further reduces the overall weight of the finished beam.

Cambering also offers increased strength; cellular beams can be profiled with the cambering process in mind, so that cells match up during the welding process.

Furthermore, Barnshaws also offers a Porthole Beam solution, where cells are cut into the section post cambering via CNC machine. Porthole Beams allow simplified integration of cells of differing shapes and sizes into the section, as the CNC machine can be programmed with the required metrics to cut the cells, rather than welding two separate tees together.

In general, selection of material and the modification of beams via fabrication can ensure the overall weight of a structure is minimised. Steel is undoubtedly the optimum choice, but by utilising services from a metal fabrication expert such as cambering and the use of cellular or Porthole Beams these inherent material benefits can be compounded to offer solutions to aid architects and those on-site. Reducing weight while promoting space efficiency is a balance that can be difficult to attain, but with modern fabrication solutions, it has never been easier.

Similar articles

More from Barnshaws Steel Bending Group

- Strawberries and beams at Wimbledon first court 28th June 2018

- Putting The Curve into Slough town centre 31st August 2017

- Barnshaws serves an ace for Wimbledon Centre Court 18th July 2017

- The effects of CE marking on modern construction 6th July 2017

Write a comment

No comments