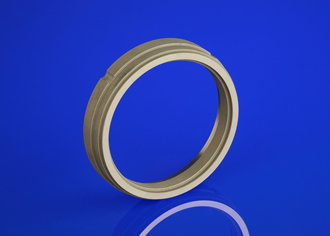

Self-lubricating material keeps pumps running

Suited for for dry or vacuum conditions which are intolerable to other carbon graphite materials, Morgan Advanced Materials has developed the MAT-240 material which allows for self-lubrication. It transfers a lubricious film which withstands dry conditions, steam and vacuum applications, as well as a range of operating environments such as marginally and fully lubricated.

MAT-240 has been successfully trialled in mixer seals featuring a dry nitrogen barrier, where no other carbon or graphite material was able to provide protection without the presence of polar gases. The material has also been proven to be suitable for methane gas, steam and air applications, including the most demanding dry applications across a temperature range from -150 to +230°C.

"Extensive internal testing has shown that the coefficient of friction of MAT-240 is less than half that of other comparable materials, meaning it offers significantly improved wear resistance. Additionally, when running in dry nitrogen, MAT-240’s friction values are again proven to be less than half the values of typical carbon and graphite materials. These properties help keep pumps and seals running for longer than has previously been possible in dry and other challenging operating conditions, maximising uptime and reducing replacement costs,” commented Michael Ritter, Morgan Advanced Materials.

Similar articles

More from Morgan Advanced Materials plc

- Safety certification leads to food packaging breakthrough 13th October 2017

- Prototype capability announced for custom piezoceramic micro tubes 20th December 2016

- Grinding capability boosted for greater pump efficiency 28th November 2016

- Global maritime security sector leads to boost in industry 16th November 2016

Write a comment

No comments