Grinding capability boosted for greater pump efficiency

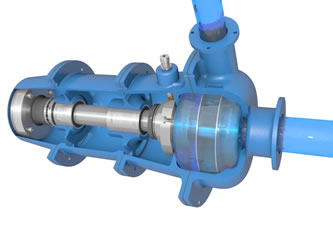

Morgan Advanced Materials has taken it upon itself to improve its grinding capability of technical ceramics, as design engineers increasingly seek out more efficient, higher performing pump components, in order to machine parts to single-digit micron tolerance.

Morgan Advanced Materials has transitioned its process capabilities in response to meet growing customer demand for improved tolerances on shafts and bearings, specifically for pump applications. The result is a more energy efficient, higher performing pump with reduced wear, improved friction, and lower running noise. This is made possible through the use of Morgan’s precision grinding technology, which the company continues to invest in.

Morgan has long advocated the use of technical ceramics over traditional materials to enhance the operational efficiency of rotor assembly in pumps. Efficiency and longevity, which are increasingly becoming more critical considerations where pump applications are concerned, can be realised through the use of Morgan’s shafts, bearings and seal components.

Not only can technical ceramics such as alumina and silicon carbide be formulated and fired into exceptional wear and corrosion resistant components, but they can also be manufactured in a variety of precision geometries.

With the growing demand to miniaturise high specification electric pumps, smaller shafts and bearings with tighter tolerances are becoming a crucial part of pump design. By achieving tighter tolerances, Morgan is helping to deliver more efficient pumps for applications in sectors including automotive, home appliances, energy, and beverage.

Chris Paine, Business Development Manager at Morgan Advanced Materials, commented: “The drive to make pumps more efficient and durable is leading manufacturers to look at every element of the design and manufacturing process to see where improvements can be made.”

Paine added: “Morgan’s direct involvement with pump customers and their design engineers has enabled optimisation of new pump designs in terms of energy and environmental efficiencies over a range of domestic, industrial and automotive pump applications.”

Similar articles

More from Morgan Advanced Materials plc

- Safety certification leads to food packaging breakthrough 13th October 2017

- Prototype capability announced for custom piezoceramic micro tubes 20th December 2016

- Grinding capability boosted for greater pump efficiency 28th November 2016

- Global maritime security sector leads to boost in industry 16th November 2016

Write a comment

No comments