Motors & Drives

Displaying 71 - 80 of 1117

Hybrid motor starters extend motor life and save space

Expanding on its extensive product line for motion control applications, Sensata Technologies has launched the Crydom DRMS Series hybrid motor starters. These hybrid starters integrate the benefits of both solid state and electromechanical relay technologies to produce a compact device that can control electrical power delivery to motors as large as 4kW. Applications range from access control, packaging equipment, lifts and escalators to industrial process control and machine tooling systems.

15th May 2019

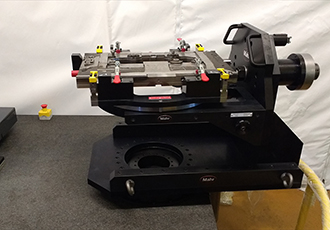

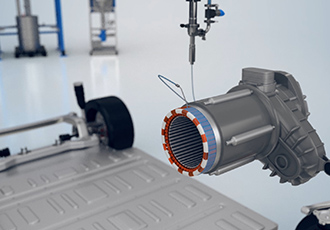

Application of low viscosity resin masses

In the production of electric motors, more precisely in the casting of the coil in the stator, very liquid, low-viscosity materials are processed. A continuous pulsation-free dispensing flow of the material is particularly important here. By trickling or impregnating the rotating drive components, the coils are provided with a protective layer.

13th May 2019

Variable speed drive liquid ring vacuum pump

A new development in the world of Liquid Ring Vacuum technology has been announced by Atlas Copco with the launch of its LRP 700-1000 VSD+ range of intelligent liquid ring vacuum pumps. A departure from the classic liquid ring pumps available in the market today, the LRP VSD+ is a compact, high performance, energy efficient system enclosed in a strong, noise-containing canopy.

10th May 2019

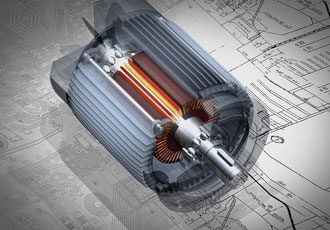

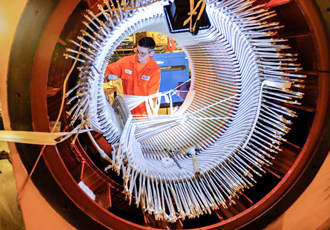

When it comes to electric motors what is best, new for old?

To repair or to replace an electric motor is a decision that often crops up in industrial settings and is one that should be given due consideration. Of course, minimising downtime is important, but there are other important factors as well. Thomas Marks, Secretary at AEMT (Association of Electrical & Mechanical Trades ), looks at what considerations should be made when it comes to repairing or replacing electric motors.

2nd May 2019

Energy saving in mines and quarries

Most mines and quarries contain a proliferation of electric motors, they vary in size and importance from large machines critical to site safety, to smaller examples that enable basic plant processes. Each one is drawing electricity and unless it is already part of a smart control solution, it could be contributing more towards energy and general cost saving.

By Trevor Herbert, Business Development Manager for Mitsubishi Electric Europe - Automation Systems Division

10th April 2019

Industrial motors market analysis and upcoming trends

Due to rapid industrialisation, there has been significant growth in manufacturing industries all around the world. As a result, the demand for industrial motors has witnessed a significant increase over the years. As per industrial motors market analysis, it is expected that the global industrial motors market will reach the total value of $58.9bn by the end of 2019 with an average growth rate of seven percent. In the emerging economies, the increasing demand for motors by downstream industries is going to be a major driver of the industrial motor market.

26th March 2019

What is the most effective way to commutate a BLDC motor?

Brushless direct current electric motors, or BLDC motors for short, are electronically commutated motors powered by a dc electric source via an external motor controller. Unlike their brushed relatives, BLDC motors rely on external controllers to achieve commutation. Put simply, commutation is the process of switching the current in the motor phases to generate motion.

By Jason Kelly, CUI

4th March 2019

Australia’s largest transport infrastructure benefits WEG motors

WEG is delivering more than 350 of its class-leading three-phase induction and electric motors to WestConnex, the largest ever transport infrastructure project in Australia and currently one of the world’s greatest engineering projects. The motors, which will be used for smoke extraction within two link tunnels, are designed to withstand a temperature 250ºC for 2 hours in an emergency situation.

28th February 2019

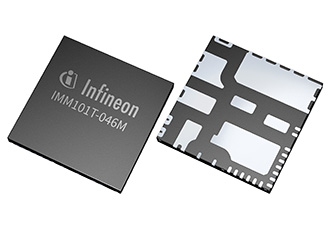

Smart IPM motor controllers for BLDC motor drives

Smart IPM motor controllers featuring full hardware and software integration needed for BLDC motor drives of up to 80W without heatsink have been introduced by Infineon Technologies. The new iMOTION IMM100 series combines the motor controller IC and a three-phase inverter stage in a single, highly compact 12x12mm2 PQFN package.

22nd February 2019

Motors & Drives documents

Datasheets

mit100419.jpg)