Sandvik Coromant

Address:

SE-811 81 SANDVIKEN

Sweden

Sweden

Sandvik Coromant articles

Displaying 1 - 20 of 111

Digital machining the easy way

In manufacturing, even the smallest errors can cause high costs. To reliably prevent this, Sandvik Coromant offers digital machining solutions that provide workshops with 'eyes and ears'. With the help of the CoroPlus range, consisting of innovative software and connected tools, it’s possible to optimise and prevent damage to the machine, tools and components - while also putting an end to unwanted production stops.

23rd June 2021

Sandvik launches an innovative smart packaging solution

Sandvik Coromant is launching an optimised smart packaging solution to level up its operational sustainability. Developed by R&D engineer and system developer, Maria Rajabzadeh Namaghi as part of Sandvik Coromant’s Automation Platform team, the solution uses Artificial Intelligence (AI) to determine the smallest possible packaging required to contain a product, reducing costs and CO2 emissions in the process.

2nd June 2021

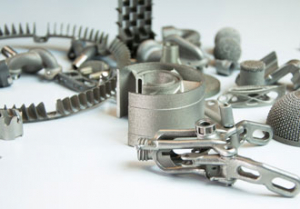

Sandvik and BEAMIT launch 3D printed super duplex

Sandvik and part subsidiary, BEAMIT Group have announced a unique capability to additively manufacture components in super duplex stainless steel. The components printed in Osprey 2507 metal powder - known and trusted for its corrosion resistance and durability - are near fully dense (more than 99.9%) and crack-free, even before post processing.

20th April 2021

Partnership to advance additive manufacturing across Middle East

Sandvik Additive Manufacturing and part subsidiary, BEAMIT have established a strategic partnership with Immensa Additive Manufacturing Group, AM solution provider in the MENA region. Immensa Technology Labs is part of the high-technology Immensa Additive Manufacturing Group, which has played a vital role in several milestone additive projects across the region, since being founded in 2016.

22nd March 2021

The road to greener hydrogen

Whether hydrogen fuel holds the key to delivering widespread renewable power remains under heavy debate. What cannot be argued is the shear investment that backers are putting into the energy source - as much as €470bn by 2050. When sceptics protest hydrogen’s potential, as both an effective and eco-friendly fuel source, it’s important that they see the bigger picture. Mats W. Lundberg, Head of Sustainability at Sandvik, examines the hydrogen roadmap.

16th February 2021

Sandvik president honoured for manufacturing contributions

Sandvik’s newly appointed executive management member, Nadine Crauwels, has been inducted into The Women in Manufacturing (WiM) Hall of Fame. The induction celebrates Crauwel’s exceptional contributions to the manufacturing sector - at a time when women represent just a third of the world’s STEM graduates.

29th October 2020

Shaping the future of manufacturing at AMB 2018

At this year’s AMB exhibition (Stuttgart, 18th-22nd September), Sandvik Coromant intends to show how customers and partners can achieve significantly higher productivity levels, more flexible machining processes and more sustainable production under the strapline ‘Shaping the future together’.

23rd July 2018

New tap designed to meet high requirements of automotive industry

A new thread forming tap has been launched by Sandvik Coromant, which is optimised for ISO P steel machining and is designed to boost productivity, particularly in the automotive industry. The CoroTap 400 achieves this by offering chip-free tapping as well as faster machining times and stronger threads through reduced torque and an optimised geometry.

1st May 2018

All-directional turning goes inside out

After the launch of the of PrimeTurning methodology and tools last year for external turning operations, Sandvik Coromant is now introducing a dedicated CoroTurn Prime SL head that makes this process available for internal turning operations. The new SL head will cater for the needs of oil and gas, aerospace and other manufacturers machining diameters in excess of 90mm (3.5”), and overhangs up to 8-10xD.

25th April 2018

Precision coolant provides thread-turning solution

Available from the 1st March, the CoroThread 266 thread-turning tool from Sandvik Coromant includes precision over- and under-coolant to improve process security and maximise efficiency. The addition of over-coolant improves chip formation for more secure machining, while under-coolant controls temperature for long and predictable tool life. Precision coolant also has positive effects on surface finish, further supporting the generation of high-quality threads.

26th February 2018

Latest parting-off tools allow dividing and conquering

A new blade for the CoroCut QD parting-off system has been unveiled by Sandvik Coromant, which in combination with new process methodology, substantially improves the tool’s stability by realigning the resultant cutting force. Among numerous benefits available to the customer are improved productivity, enhanced surface quality and reduced noise levels.

23rd January 2018

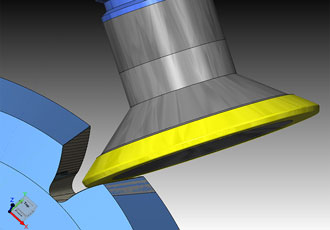

CAD/CAM software changes gear cutting with new advanced features

Extending the functionality of its InvoMilling software, cutting tool and tooling system company Sandvik Coromant have introduced the latest version of its user-friendly CAD/CAM solution for fast and simple NC programming, which offers even more possibilities when manufacturing gears on universal five-axis machining centres. As of late 2017, the software will also enable customers to produce straight bevel gears and herringbone gears.

15th January 2018

Is there an ace in the hole?

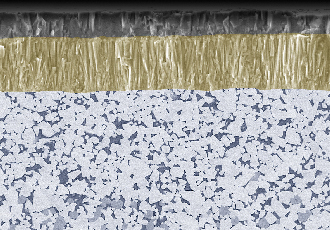

In order to overcome the challenges of chip formation and evacuation when drilling non-ferrous metals, cutting tool and tooling system company, Sandvik Coromant has announced its CoroDrill 880 CVD diamond-coated insert grades, GCN124 and GCN134. The properties of the diamond coating provide long tool life and combine with a chip breaker and geometry designs to guarantee performance when drilling materials such as aluminium.

3rd January 2018

Tool holders enable turning in all directions

Cutting tool and tooling system company, Sandvik Coromant, has unveiled a new range of CoroTurn Prime multi-task and axial type tool holders to help machine shops implement the new PrimeTurning methodology, which enables turning in all directions. The introductions allow users to maximise the benefits of PrimeTurningon multi-task turn-mill centres and vertical turning lathes (VTLs). Complementing the company’s existing radial tool holders, Sandvik Coromant now has a complete offer for PrimeTurning operations.

10th October 2017

Taking a step in the right direction towards Industry 4.0

With an advanced solution that enables manufacturing companies to take steps towards digital machining and Industry 4.0, cutting tool and tooling system supplier Sandvik Coromant has introduced connectivity capability to its series of Silent Tools tool holders. The innovation is offered as part of the company’s CoroPlus suite of connected solutions for machine shops keen to embrace the rapidly advancing trend of industry digitalisation.

28th September 2017

High-feed face mill speeds up productivity

A new high-feed version of the CoroMill 745 face milling cutter, has been unveiled by Sandvik Coromant, featuring a 25° entering angle for additional productivity gains when milling steel and cast iron workpieces. The new high-feed version facilitates even higher metal removal rates (MRR) in applications with depths of cut up to 2.8mm (0.110”). The new cutter is set to benefit sectors such as die and mould, pump and valve, oil and gas, automotive, power generation and general engineering.

28th July 2017

The right route for successful composites machining

Optimised milling and slotting operations are now offered in the new CoroMill Plura routers unveiled by Sandvik Coromant, and are offered in composite materials such as CFRP (carbon fibre reinforced plastic) and GFRP (glass fibre reinforced plastic). Production engineers, machine shop managers and operators will all benefit from the patented geometries provided by the new routers, particularly those in the aerospace industry, where these materials are increasingly prevalent, as well as others in sectors such as automotive, motorsport, wind power and marine.

11th July 2017

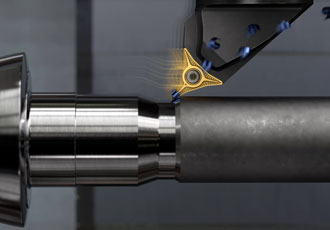

Insert grade overcomes instability and vibration in steel turning

The new GC4335 insert grade for the turning of steels where unstable conditions or vibration issues prevail has been introduced by cutting tool and tooling system manufacturer, Sandvik Coromant. GC4335 is designed to bring about secure and predictable machining, as well as shorter cycle times and better machine utilisation through reduced stoppages and longer insert life. Customers will benefit from an improved process with less risk of insert breakage, as well as reduced cost per component and faster return on investment.

25th April 2017

.jpg)