Burkert Fluid Control Systems

Address:

Fluid Control Centre

1 Bridge End

Cirencester

Gloucestershire

GL7 1QY

United Kingdom

1 Bridge End

Cirencester

Gloucestershire

GL7 1QY

United Kingdom

Burkert Fluid Control Systems articles

Displaying 101 - 120 of 139

Burkert Provides Complete Process Control System For New Mersen Eurocentral Facility

Burkert has provided a complete process control system, including level and flow monitoring, fluid control and process actuation, for a new Moulding Station and Effluent Treatment plant, installed at Mersen’s new production facility at Eurocentral in Scotland. The Burkert control system is integral to the new moulding and treatment facilities, automating what was previously a manual manufacturing process, to improve its quality, yield and output volume.

13th September 2010

Integrating Instrumentation Monitoring Increases Process Efficiency and Membrane Life in Reverse Osmosis Processes

Scaling, fouling and oxidation are the natural enemies of reverse osmosis (RO) systems in water processing units—especially in the food and pharmaceutical industries. Proper process monitoring and control of critical parameters, such as pH, ORP, conductivity, flow, temperature and differential pressure can provide advanced warning and protection of a scaling, fouling or chemically attacked RO element. If these early warnings are ignored, the membrane may be damaged beyond the point that chemical cleaning can restore the system back to its original operating efficiency.

20th August 2010

INTEGRATED VALVE SYSTEMS ELIMINATE DISADVANTAGES OF CONVENTIONAL AUTOMATION CONCEPTS IN HYGIENIC PROCESSES

With the development of practical solutions that integrate automation functions into the pneumatic actuators of process valves, decentralised automation systems have become a real alternative to control cabinet systems in many process sectors. Food and beverage producers, as well as companies in the pharmaceutical and cosmetics sectors are now in a position to reconcile the commercial necessity of a high degree of automation of their production with the requirements of hygiene and safety. Thanks to their modular structure, systems based on intelligent process valves can be adapted to suit many situations and applications, whereby such optimised solutions are always based on high-quality, tried and tested components with a long service life.

8th July 2010

Burkert Provides Complete ATEX Process Package on New Generation Fuelmatic for the Production of Bio-Diesel

Bürkert Fluid Control Systems has partnered with Green Fuels Ltd., the World’s leading biodiesel equipment manufacturer, providing a complete package of ATEX- rated valves, flow sensors, level switches, positioner systems and conductivity and flow meters, for Green Fuels’ latest Fuelmatic system. Designed to produce up to 20,000 litres per day of the highest quality biodiesel, the fully automated Fuelmatic is skid- mounted for ease of shipping and installation. It is attracting worldwide interest, with the 20th Fuelmatic currently being commissioned Mexico.

24th June 2010

Burkert’s AirLINE Ex 8650 System Allows Safe Combination of Pneumatics & Electronics in Zone 1 Blending System for N.Sea.

Burkert’s ex-proof AirLINE Ex 8650 system, working in conjunction with modules from the intrinsically safe Siemens SIMATIC ET 200iSPTM system, has provided the ideal solution in a recent North Sea project for Jiskoot an internationally recognised manufacturer and supplier of Zone 1 control, sampling and blending systems to the oil and gas industry.

20th May 2010

Burkert’s Decentralised Method of Opening & Closing Process Valves Eliminates Energy Losses from Wasteful Venting of Control Air

The cost-down pressures inherent in all process industries mean that plant operators are consistently required to improve efficiency, at the same time as ensuring repeatable product quality. In pursuit of efficiency, companies are prepared to invest heavily in new plant and equipment. However, in many cases, real savings and efficiency improvements can be achieved relatively simply and at low cost by focussing on cutting energy usage.

4th May 2010

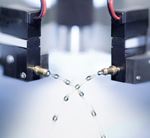

Modular, Tailor-made Cooling Systems can Guarantee Zero Leakage on Robotic Welding Systems Due to Welding Tip Loss

By using configurable, modular control systems with operator-specific software, users of spot welding robot systems can acquire intelligent tailor-made cooling systems that guarantee zero leakage in their production environment as a result of loss or replacement of electrode tips. Such modular systems, consisting of compact devices with integrated sensor equipment, valves and controllers, can be individually configured to provide optimised cooling solutions for specific applications and operator requirements. Moreover, in contrast to conventional solutions consisting of products from various manufacturers, integrated solutions are much more compact in size and their components are specially chosen for optimised interoperability.

11th March 2010

Patented Flipper Technology Enables New Miniature 3/2 Isolation Valve to Set New Benchmark in Analytical & Biomedical Tasks.

Burkert’s innovative Type 6650 3/2 isolation valve uses patented flipper technology to set a new benchmark for miniature solenoid valves employed in clinical, life-science, analytical and fluid handling equipment. Suitable for use on vacuum, at up to 7-bar, and providing medium isolation for aggressive fluids, the direct-acting Type 6650 - at just 4.5mm wide - is a significant step towards miniaturisation, while outperforming comparable 10mm and 16mm designs.

11th March 2010

New Integrated Liquid Flow Controller Provides Cost Saving Solution For Dynamic Measurement Of Small Liquid/Gas Flows

The integration of sensor, control electronics and proportional valves into a single compact device enables Burkert’s new Liquid Flow Controller (LFC) to provide fast and accurate measurement and dosage of small volumes of liquids with nominal flow rates of 10 – 600 ml/min (0.6 to 36 l/h) with a 1:10. measuring span.

11th March 2010

Liquid Flow Controller

The intelligent combination of high-performance flow-rate measurements and a highly precise proportional valve turns Bürkert´s Liquid Flow Controller into a perfect solution for a large number of industrial applications. The integration of sensor, control electronics and proportional valves into a single compact device make the Liquid Flow Controller ideally suited for applications requiring the fully-automatic metered dosing of small amounts of liquids.

18th December 2009

Burkert’s New Intelligent SideControl Brings Flexibility, Precision & Ease-of-Use to Positioner & Process Control Tasks

Burkert’s new 8792/8793 SideControl units are versatile, robust and easy- to- use positioners/process controllers designed for flexible mounting onto linear and rotary actuators, (according to IEC534-6/VDI/VDE 3845 Namur), and also Burkert process valves. The SideControllers offer excellent control accuracy and outstanding dynamic properties in positioning and decentralised process control tasks; they are suitable for a wide range of applications in sectors such as Hygienic Processing, Water treatment, Steam and Gas Handling, typically in the control of auxiliary processes -water, steam, air, heating and cooling.

26th November 2009

Burkert’s ATEX-Rated, Electrically Actuated Ball Valves Provide Safe Shut Off for Fuel Oils in Overfill Alarm Systems

Burkert’s 8804 ATEX- rated electrically actuated ball valves are providing the safe shut off of heating oil and diesel fuels at multiple depots operated by one of the UK’s largest fuel distributors. The valves are employed by flow and level measuring specialists, Severn Instruments, as part of the company’s tank overfill protection alarm system (TOPAS). The TOPAS system is critical to safe and efficient operation at fuel depots, as fuel spillages are potentially hazardous and cost around £1,000 per litre to clean up.

26th November 2009

Burkert Robolux Valves Reduce Valve Requirement from 8 to 4, & Eliminate Deadlegs on Asthma Inhaler Cartridge Machine

Burkert has supplied a Robolux valve system on a machine that fills asthma inhaler cartridges for a multinational pharmaceutical company. The unique Robolux design has enabled Burkert to reduce the costs of the system drastically, by cutting the valve requirement from eight diaphragm valves down to four. In addition, because Burkert’s integrated design has only one block – compared to two for competitors - there are fewer weld connections for the customer to make, reducing installation time and validation costs; and the integrated design also means that internal volumes are smaller, eliminating deadlegs and maximising sterility.

16th October 2009

Redesigned Miniature Valve Technology Sets Standards For Size & Performance In Laboratory, Analysis & Medical Engineering

Isolated miniature solenoid valves (IMSV) that provide maximum power from a minimum sized envelope are the current demand of original equipment manufacturers (OEMs) in the field of laboratory and analysis technology, and also medical engineering. In clinical diagnostics, flow-rate and reliability are essential, while cleanliness is given top priority. In automated analytics, standard procedures such as titration, defined sampling and the precise dosage of reagents, based on integrated fluid control systems, require pinpoint precision and repeatability. In addition, manufacturers and users, when opting for a certain type of IMSV, also consider cost, wetted material type, cleanability, dosage capacity and flushing characteristics of the valve.

9th October 2009

Burkert Robolux Units Reduce Diaphragm Valve Requirement By 75%, Eliminate Deadlegs & Cut Cycle Times On Sterile Filling Unit

Burkert’s Robolux valves have eliminated deadlegs and reduced the requirement for diaphragm valves from 8 to 2 on sterile filling units used in the production of Pulmicort, one of the world's leading asthma medicines. The Robolux valves have also greatly simplified the design of the filling units, cutting cycle times and making maintenance and cleaning procedures far easier to carry out.

2nd October 2009

Burkert pneumatics control pharmaceutical tablet production

Buck Systems, part of GEA Pharma Systems based in Birmingham UK is using Burkert to sub-contract supply pneumatic control systems for it’s leading edge powder processing plant equipment used in one of the world’s largest and most advanced tablet manufacturing plants in the Far East.

24th September 2009

Burkert alliance with BBS systems provides single source solution for hygienic processing in pharma & biotech markets

Bürkert and BBS-Systems AG of Switzerland have formed an alliance that offers combined competence and a single source for specific system solutions in the pharmaceutical, biotechnology, chemical- and food market sectors. The alliance provides a unique synergy of Burkert’s valve, sensor, process control, hazardous area and specialist products with BBS’s sterile range of ancillary piping, flanges, connectors, indicators, sampling systems and vessel equipment.

21st August 2009