Redesigned Miniature Valve Technology Sets Standards For Size & Performance In Laboratory, Analysis & Medical Engineering

9th October 2009

Source:

Burkert Fluid Control Systems

Isolated miniature solenoid valves (IMSV) that provide maximum power from a minimum sized envelope are the current demand of original equipment manufacturers (OEMs) in the field of laboratory and analysis technology, and also medical engineering. In clinical diagnostics, flow-rate and reliability are essential, while cleanliness is given top priority. In automated analytics, standard procedures such as titration, defined sampling and the precise dosage of reagents, based on integrated fluid control systems, require pinpoint precision and repeatability. In addition, manufacturers and users, when opting for a certain type of IMSV, also consider cost, wetted material type, cleanability, dosage capacity and flushing characteristics of the valve.

Flipper versus rocker valve

Until very recently the operating principle of rocker valves - as introduced by German manufacturer, Bürkert, in the early 1990’s had been considered state-of-the-art in valve technology. It set the standards for most miniature valves, especially with IVD devices, and has been copied many times. Owing to their diaphragm operation, rocker valves can process very small volumes and are easy to rinse. This has made them first choice in invitro diagnostic applications. However, since diaphragms react with a certain deceleration, rocker valves are less suitable for high speed or high precision applications.

This is not the case with flipper valves; they have no diaphragm, so the pumping effect at the outlet of the valve is almost completely excluded – a big advantage when high precision dosing is needed. They are also suitable for small volumes, working quickly and being more durable than rocker valves with their sensitive diaphragm. However, due to their particular design, flipper valves usually have a larger internal volume than valves based on diaphragm technology of a comparable size. This increased volume, and especially the cleanability aspect of the valves, have, so far, been considered as the biggest disadvantages of flipper technology.

Despite its disadvantages, Bürkert did not give up on the flipper valve - even though the company had developed its more successful competitor. Instead, Bürkert sought to eliminate all the known problems with the technology. With the help of advanced digital R&D tools, researchers were successful in developing alternatives to the existing construction principles of flipper valves. Bürkert’s engineers used computer-simulated flows and pressure paths and applied the finite element method (FEM) to optimise their calculations.

The FEM calculations supported the design of the body of the valve, so as to avoid residues that are typical in contaminated systems. Different mouldings were tested and the position of the valve seats was also iteratively defined. The resulting optimised internal design enables effective flushing of mediums through the device, in a way that was only previously possible with rocker valves. This eliminates the waste of expensive reagents, as well as preventing cross contamination and increasing process safety.

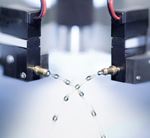

The flushing characteristics of the second-generation flipper valve are related not only to the valve’s internal volume, but more principally to its internal design. This becomes clear when comparing Bürkert’s Type 0127 rocker valve with the company’s new Type 6650 flipper isolation valve. The internal volume of the Type 6650 valve is two times smaller than the rocker valve’s volume. Moreover, the 6650 is only 4.5mm wide - much smaller than previous models, yet it delivers greatly improved flow rates. The major advantage of this size reduction is that equipment and instrument manufacturers can pack more valves into the same space for greater functionality. This provides savings in laboratory costs as equipment and instrument sizes can be reduced, overall.

In addition to its size advantages, Burkert’s second generation flipper valve also delivers improved performance. The valves have short – and reliable – response times; and have high repeatability and excellent flushing characteristics. These advantages – combined with the valve’s reduced size – mean that the 6650 valves are particularly suitable for the handling of liquids with micro plates where high-precision dispensing and small dimensions are required.

Until very recently the operating principle of rocker valves - as introduced by German manufacturer, Bürkert, in the early 1990’s had been considered state-of-the-art in valve technology. It set the standards for most miniature valves, especially with IVD devices, and has been copied many times. Owing to their diaphragm operation, rocker valves can process very small volumes and are easy to rinse. This has made them first choice in invitro diagnostic applications. However, since diaphragms react with a certain deceleration, rocker valves are less suitable for high speed or high precision applications.

This is not the case with flipper valves; they have no diaphragm, so the pumping effect at the outlet of the valve is almost completely excluded – a big advantage when high precision dosing is needed. They are also suitable for small volumes, working quickly and being more durable than rocker valves with their sensitive diaphragm. However, due to their particular design, flipper valves usually have a larger internal volume than valves based on diaphragm technology of a comparable size. This increased volume, and especially the cleanability aspect of the valves, have, so far, been considered as the biggest disadvantages of flipper technology.

Despite its disadvantages, Bürkert did not give up on the flipper valve - even though the company had developed its more successful competitor. Instead, Bürkert sought to eliminate all the known problems with the technology. With the help of advanced digital R&D tools, researchers were successful in developing alternatives to the existing construction principles of flipper valves. Bürkert’s engineers used computer-simulated flows and pressure paths and applied the finite element method (FEM) to optimise their calculations.

The FEM calculations supported the design of the body of the valve, so as to avoid residues that are typical in contaminated systems. Different mouldings were tested and the position of the valve seats was also iteratively defined. The resulting optimised internal design enables effective flushing of mediums through the device, in a way that was only previously possible with rocker valves. This eliminates the waste of expensive reagents, as well as preventing cross contamination and increasing process safety.

The flushing characteristics of the second-generation flipper valve are related not only to the valve’s internal volume, but more principally to its internal design. This becomes clear when comparing Bürkert’s Type 0127 rocker valve with the company’s new Type 6650 flipper isolation valve. The internal volume of the Type 6650 valve is two times smaller than the rocker valve’s volume. Moreover, the 6650 is only 4.5mm wide - much smaller than previous models, yet it delivers greatly improved flow rates. The major advantage of this size reduction is that equipment and instrument manufacturers can pack more valves into the same space for greater functionality. This provides savings in laboratory costs as equipment and instrument sizes can be reduced, overall.

In addition to its size advantages, Burkert’s second generation flipper valve also delivers improved performance. The valves have short – and reliable – response times; and have high repeatability and excellent flushing characteristics. These advantages – combined with the valve’s reduced size – mean that the 6650 valves are particularly suitable for the handling of liquids with micro plates where high-precision dispensing and small dimensions are required.

Similar articles

More from Burkert Fluid Control Systems

- Continuous water quality analysis for boreholes 6th July 2020

- Controller delivers precision microlitre dosing 14th May 2020

- Multi-medium testing facility for fluidic components 19th March 2020

- Micro precision for time-pressure dosing 10th December 2019

Write a comment

No comments