Burkert Fluid Control Systems

Address:

Fluid Control Centre

1 Bridge End

Cirencester

Gloucestershire

GL7 1QY

United Kingdom

1 Bridge End

Cirencester

Gloucestershire

GL7 1QY

United Kingdom

Burkert Fluid Control Systems articles

Displaying 1 - 20 of 139

Continuous water quality analysis for boreholes

Continuous water extraction from boreholes is a common source of raw materials for drinks manufacturers as well as water utility companies. In all cases, monitoring water quality is very important, both pre and post treatment, and the frequency of tests establishes the confidence in the data. Bürkert’s Type 8905 Online Analysis System offers continuous monitoring of various water parameters with minimal intervention or maintenance.

6th July 2020

Controller delivers precision microlitre dosing

A time-pressure controller developed for precision dosing of microlitre volumes for medical and pharmaceutical applications has been launched by Bürkert.

14th May 2020

Multi-medium testing facility for fluidic components

The requirements placed on the service life, reliability and functionality of fluidic components in process technology – especially in the pharmaceutical and food industries – are increasing all the time.

19th March 2020

Enhancing radar level measurement for hygienic applications

Those facing challenges in measuring fluid levels in hygienic applications should be aware of Bürkert’s new Type 8139 non-contact radar measuring device. Designed to provide highly accurate, continuous measurement for specialised tanks that contain difficult to measure fluids, the Type 8139 is optimised to meet the needs of the pharmaceutical, food and beverage and water industries.

9th October 2019

Fast, convenient water quality monitoring solutions

Water is used in so many ways throughout the food and beverage industry, even as the final product, which means the quality of that water needs to be carefully monitored. With such an influence on the finished product, precise water quality monitoring can provide the key to consistent quality output, so is it time to look at the next generation of compact continuous analysis solutions?

8th October 2019

Taking on the challenges of flow measurement

Manufacturers in the food and beverage industry have two main priorities: product quality and hygiene. For those operating with different fluids, from fruit juice to milk, chocolate and beer, there are many challenges in measuring flow while at the same time minimising waste and energy usage.

26th September 2019

Smart water monitoring Down Under

Providing high quality water supplies is an essential service delivered by municipal authorities and utility companies around the world. Maintaining water quality requires constant monitoring and testing to ensure accurate measurements are being taken. Traditionally this has involved time-consuming calibration and maintenance.

25th July 2019

Pharmaceutical supplier opts for innovative hygienic flowmeter

Specialist process machinery manufacturer, L.B. Bohle, has developed a cleaning system for the pharmaceutical industry using Bürkert’s innovative FLOWave flowmeter for a compact, hygienic and very accurate process. Incorporating the latest in flow measurement technology has minimised equipment footprint and reduced operating costs as well as maintenance time.

29th May 2019

Reliable water treatment in remote communities

Delivering high quality water supplies to remote communities can be a considerable challenge for water authorities, but a combination of engineering skills and innovative process control equipment has delivered a solution. Ross-shire Engineering (RSE) is using mass flow controllers from Bürkert to ensure pH levels are maintained at optimum levels.

16th April 2019

Flowmeter innovation moves forward

Bürkert has released the latest update to its FLOWave flowmeter, which offers greater functionality and widens its appeal for the pharmaceutical sector as well as food and beverage applications. The list of new capabilities includes the ability to detect different fluids, which will open-up new applications in many areas.

26th March 2019

Finding the best partner for hygienic process control projects

Precision control of fluids and gases is a task that requires technical knowledge and experience. Within this area, hygienic applications, such as those in the pharmaceutical and biotech industries, place even higher demands on the control components and the surrounding infrastructure.

27th February 2019

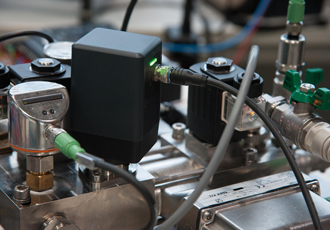

Tackling pollution control in diesel generating sets

The introduction of Tier 4 and Tier 5 emissions regulations continue to have an impact on manufacturers of diesel engines and the final products in which they are used. Tier 4 has already been implemented for non-emergency generating sets and it seems only a matter of time before they will have to meet Tier 5 requirements. To help manufacturers meet both current and future emissions regulations, Burkert can develop complete dosing packages for selective catalytic reduction (SCR) systems.

19th December 2018

Marstons is chilling with Burkert

For Marstons brewery in Burton upon Trent, Staffordshire, replacing control valves on the main chiller system would improve reliability. However, the process control components were initially looking expensive - that is until a call to Burkert revealed a much more cost-effective solution. Replacing ageing equipment or expanding a production line are suitable opportunities to take stock of new technologies and how they can improve productivity and reduce project costs.

11th December 2018

Hygienic solutions at EHEDG Conference 2018

Professionals operating in hygienic sectors will be able to meet with Burkert at this year’s European Hygienic Engineering and Design Group (EHEDG) Conference in London from the 21st to 22nd November, with the business demonstrating EHEDG approved solutions for food and beverage applications.

16th November 2018

Jamaican patties still a favourite thanks to valves

June this year marked 30 years that Cleone Foods has produced Jamaican patties and distributed them under its Island Delight brand name. Working for such a long time, the company relies on its process equipment to ensure an uninterrupted supply of its tasty products and Burkert has proven itself up to the task with process valves that have been in operation for ten years before requiring a service.

13th November 2018

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)