Reducing risks of contamination in the food industry

Elevator buckets that become worn and damaged through typical manufacturing operations may contaminate the food with fragments and particles of various sizes. The potential for contamination has increased industry demand for all plastic parts that come into contact with food directly or indirectly to be detectable and compliant with food industry standards and specifications.

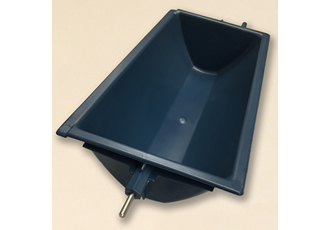

To reduce the risk of contamination, Apollo Group chose a LUVOCOM high-performance detectable compound to replace a non-detectable nylon 6 material previously used in its elevator buckets.

Bertil Elders, Spare Parts Manager with Apollo Group said: “We needed a highly reliable material because the machine transports food products and we chose LUVOCOM 3-9001/BL/L because it guarantees hygienic safety.”

Elders added: “Our bucket elevators with LUVOCOM buckets are currently being used by a number of global food manufacturers including chocolate and candy producers to ensure product safety for their consumers.”

LUVOCOM is compliant with food contact regulations such as EU 10/2011 and FDA CFR 21.177. It is coloured blue to make visual traceability easier and it meets the mechanical requirements of the buckets including stiffness and impact resistance.

Because LUVOCOM 3-9001/BL/L is magnetic, the presence of fragments or particles can be detected by common metal or x-ray detectors used in food production lines.

Robert Healy, General Manager, LEHVOSS North America, said: “For example if a piece of the bucket, because of a breakage, were to contaminate the food, it can be detected later in the process by the detection line and separated automatically.”

Contaminated parts can be apprehended and reliably rejected, even when the foreign particles are down to 1mm (0.04”) in size.

LUVOCOM high-performance detectable compounds are available in a wide range of thermoplastic materials including PE, PP, PA, POM to PES and PEEK.

“Practically all thermoplastic materials can be supplied with the detectable characteristic,” added Healy.

Apollo bucket elevators combine horizontal and vertical transport in one installation. They are easy to install, highly reliable, and have low maintenance requirements. They are used for conveying a broad range of bulk products in the food, agriculture, pharmaceutical, cosmetic, chemical, ceramic, glass, recycling, building and metallurgy industries as well as other materials requiring gentle handling such as grains, coffee, sweets, sugar, rice, beans, pet food, peanuts, seeds and tea.

Similar articles

More from Electronic Specifier

- Building the case for construction offices in 2021 20th May 2021

- UK construction: is the industry finally on the up? 26th August 2020

- Speaking to a younger generation of women in tech 11th August 2020

- Engineering firms encouraged to get ‘2020’ vision 6th January 2020

Write a comment

No comments