Redex gears revolutionise the versatility of vertical lathes

Redex announces the release of a new drive solution for rotary tables of multi-axis milling machines. The high-speed versions of its DRP, KRP and KRPX ranges complement the features of its MSR range of drives. Compared with more conventional solutions, such as combining indexing tables with direct-drive tables, both of these one-of-a-kind solutions provide real added value to machine-tool manufacturers.

They dramatically simplify the design of the mechanical transmission systems of both large rotary tables used on vertical lathes (over 2000 m) and smaller tables used on milling machines. They also improve machine accuracy and allow for smaller machine footprints.

With these two complementary solutions, Redex once again provides machine-tool manufacturers with cutting-edge turnkey drives that are innovative, more user friendly and easier to maintain.

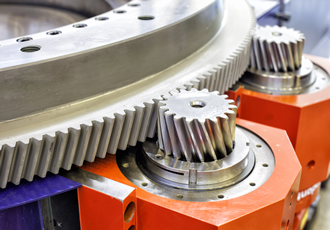

The high-speed versions of the DRP, KRP and KRPX drives use the heart of Redex high-performance planetary reducers. Widely recognised by the most demanding manufacturers, they have extensively proven their worth amongst other drives for large-capacity machine-tools.

When meshed with a drive gear, the two reducers on Redex TwinDrive and DualDrive solutions cancel 100% of backlash. This guarantees the exceptional accuracy and momentum of Redex drives, which have extensively proven their worth on linear rack-and-pinion systems for many years.

These high-speed reducers have been "hardened" (using in particular Redex know-how in spindle gearboxes) to allow continuous operating cycles and meet the specific requirements of rotary tables. As a result, Redex high-speed TwinDrive and DualDrive units can achieve rotational speeds of up to 28 rpm-1.

Although the Redex MSR range offers higher rotational speeds, the high-speed versions of its DRP, KRP and KRPX drives offer far greater accuracy, rigidity and momentum. They are the standard drives with the highest positioning accuracy (a few arc-minutes).

The complementarity of both solutions allows manufacturers to design the right rotary-table drives for specific applications and thus their priorities of speed, power, accuracy and rigidity.

Substantial advantages over conventional solutions Redex is the only manufacturer of one-of-a-kind integrated drive systems for rotary tables on vertical turning lathes. Before, rotary tables were designed to use two different types of drives when a C-axis was required:

- a main drive for turning operations, driven by a large spindle motor.

- and a feed-preloaded gearbox to cancel the backlash during C-axis mode and which needed to be clutched and unclutched to the crown in order to shift to milling. In addition, the main drive would have to be shifted to neutral ratio.

Thanks to the exclusive features offered by the quality of their high-performance reducers and the association of these reducers in TwinDrive or DualDrive mode, Redex solutions offer the highest positioning accuracy. They also make it possible to execute additional functions on the C-axis without any additional mechanical devices or the use of position locking. This maximum accuracy is maintained during milling and/or positioning operations particularly by the electrical or mechanical preload system, which continuously manages the counter-torque between the pinions.

Solutions that use two reducers, and thus two motors, are more cost effective and easier to manage in most cases. Compared to heavy-duty rotary tables used in conventional configurations that require a 160-kW motor, the TwinDrive solution uses two 80-kW motors, which are more standard and often less expensive (even accounting for the cost of both units). Maintenance and spare-parts management is also greatly simplified by the use of the smaller, standard motors.

Last but not least, this dramatically simplifies rotary-table design because it eliminates the need for machine-tool manufacturers to design and build their own gearboxes with all the necessary components.

Similar articles

More from REDEX ANDANTEX

- Redex gears revolutionise the versatility of vertical lathes 18th November 2014

- High-Speed Fiber placement on large complex structures 22nd June 2011

- MSR Turning Table Drive Solutions 25th November 2010

- X-block, the most compact wire and cable tension controller on the market 4th August 2010

-(1)ed.jpg)

Write a comment

No comments