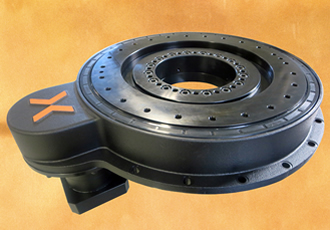

Precision ring drive system is optimised for high speed

With precision grade bearing and drive mechanism in a sealed housing, Nexen Group has introduced the Compact Ring Drive system (CRD). Freely programmable, the three-drive design configurations allow the CRD to be optimised for high speed, high torque or both, depending on the application.

With a 250 or 350mm dial plate bolt circle diameter and a large open centre; users can optimise performance in a small space. The combination of Nexen’s roller pinion technology with integrated bearing and motor/gearhead deliver a rigid, smooth system with zero backlash options from the motor through the driven load.

The CRD is ideal for applications including cutting systems, gantry systems, medical products, robotics, aerospace, machine tool, semiconductor and material handling.

Benefits of Nexen’s compact precision ring drive system include indexing precision up to 30ArcSec and repeatability up to 5.1ArcSec. Zero backlash options are available. The CRD system is smooth in motion. It has a high output load capacity of up to 108kN, and can handle speeds of up to 225RPM.

Similar articles

More from Nexen Group Inc

- Precision rotary motion control in measuring system 22nd May 2019

- Zero-backlash spring engaged brakes for power transmission apps 24th April 2018

- Zero-backlash spring engaged brake family for power transmission 7th March 2018

- Compact ring drive has zero backlash and zero added envelope 18th December 2017

-(1)ed.jpg)

Write a comment

No comments