How to manufacture better universal joints

Vehicle Original Equipment Manufacturers (OEMs) ask for three things when sourcing vehicle parts: good price, quality and service. Here, Nick Jordan, Head of Engineering and Quality at Pailton Engineering, explains how one assembly process at its headquarters in Coventry, UK has amped up all three of these ever-important factors. Universal joints play a critical role in the steering system.

They must transmit rotational input torque through the entire steering system via varying angles, at a consistent speed, without resistance of radial play. Get it wrong, and the vehicle can exhibit reduced steering precision, leading to increased driver fatigue and vehicle maintenance costs.

Assembling the universal joint was inherently a manual process for Pailton Engineering, combining a bearing assembly inside two yokes with one high pressure press by a highly skilled operator. This method of staking universal joints is still widely used across the vehicle parts industry and is fit for purpose, but Pailton Engineering is always striving to continually improve.

The first improvement being consistency - manual processes are vulnerable to human error. The second being pressure - applying such a high pressure force to a material can affect the material’s physical integrity. If it can be avoided, it should be avoided.

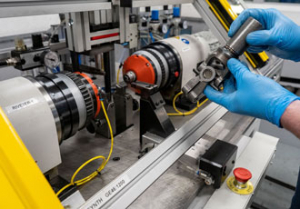

That’s why Pailton Engineering invested in two bespoke universal joint staking rigs, transforming the manual process, into an automated one. The two machines can run simultaneously, to stake 19mm or 15mm universal joint variants.

A huge benefit of these machines is the quality assurance and consistency of component assembly. Every universal joint in a batch is assembled to the exact same high quality standards. Similarly, data recorded by the machines offers full traceability to show how the universal joint was built, including assembly pressure parameters.

With this more controlled method of staking universal joints, we’ve been able to significantly reduce the pressure used within the process compared with the manual method, while maintaining functionality and quality. This offers a multitude of benefits providing a higher quality and longer lasting part for the end-user.

Precise and accurate bearing assembly in the universal joint also enables smooth rotation over the lifespan of the steering system. This is especially important for vehicles where the steering tilt and telescope functions are adjusted daily, for improved driving ergonomics, comfort and safety.

The equipment has been installed in its own purpose-built clean room work area that is solely focused on universal joint assembly. The investment in equipment and overall performance is making bearing installation and universal joint assembly an easier and more consistent process.

Convinced by our automated processes and assured product integrity, vehicle OEMs can now begin to focus on other options in universal joint sourcing. Whether they choose regreasable or service free universal joints, with high working angles and non-standard interface options, they can be confident they are getting quality parts.

The new investment in Pailton Engineering’s assembly line has further increased Pailton’s consistency, traceability and longevity. These requests from OEMs are no longer a luxury, but an expectation. By strategically targeting the universal joint staking process, we’ve transformed a manual process into an intelligently designed automated assembly cell.

Similar articles

More from Pailton Engineering Ltd.

- How to manufacture better universal joints 2nd December 2020

- Green engineering for the commercial vehicle sector 28th August 2020

- Let's debunk the myths surrounding women in engineering 18th June 2018

- Bevel box design is a step up with upgraded sealing capabilities 27th April 2017

-(1)ed.jpg)

Write a comment

No comments