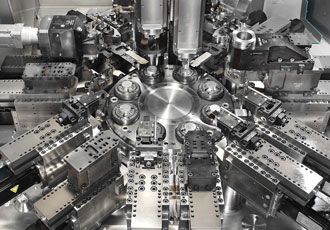

Eight spindle multi for turn milling components from 40mm bar

German turning machine builder, Index, has launched a second eight spindle CNC multi-spindle automatic, designated MS40-8, capable of turn-milling components from bar up to 40mm diameter. The manufacturer’s first eight spindle multi, with a bar capacity of 24mm, was introduced in 2011. Machine availability in the UK and Ireland is through sole sales and service agent, Geo Kingsbury, Gosport.

CNC multis normally have six spindles. The two additional stations facilitate the complete manufacture of components of even higher complexity in the short cycle times for which the lathes are renowned. Alternatively, simpler parts can be produced in half the time using the machine as a double four spindle auto, indexing the drum by 90° each time instead of 45° to produce two parts per cycle.

The MS40-8, which is also capable of chucking cast, forged or extruded parts up to 80mm in diameter, is suitable for high volume production in the automotive, connector and aerospace industries in particular. However, smaller batches can be produced almost as efficiently and economically as larger runs due to the speed of set-up inherent with CNC rather than cam technology. In addition to turning, cycles may include drilling, elliptical deburring of cross holes, milling, hobbing, tooth milling, deep-hole drilling and slotting.

The machine has up to 18 CNC cross slides (X and Z) and additional Y axes as an option. The low mass slides with hydrostatic support are wear-free and avoid stick-slip. Low moment of inertia leads to highly dynamic movement for rapid acceleration, while outstanding damping characteristics prevent the transfer of machining vibrations to the adjacent slide via the headstock. It allows, for example, heavy-duty roughing at one station while high-precision finishing takes place at another, without sacrificing surface quality.

Each of the eight spindles in the compact drum is fluid-cooled to minimise thermal growth. They are rated at 24kW/7,000rpm/57Nm and are characterised by independent, infinitely variable speed control. Cutting parameters are therefore not compromised at any station, enhancing dimensional accuracy of components, their surface finish and tool life. C-axes are available in all spindle positions, permitting complete machining of complex workpieces in conjunction with live tools on the compound slides.

Two pivoting back-working spindles can perform simultaneous operations on the rear of components in conjunction with seven dedicated tools, four of which may be live. The spindles are locked into position by three-part Hirth couplings, guaranteeing a high level of stiffness so that heavy cutting does not compromise machining precision.

Energy efficiency is central to the machine's design. Weight-optimised components reduce energy consumption and increase dynamic response. Energy recovery by means of regenerative drives is included and units that consume large amounts of energy are put into standby after a user-defined time. Friction is minimised using optimally paired materials and hydrostatic bearings and intelligent cooling principles are employed for targeted cooling of the machine and reuse of waste heat.

Similar articles

More from Geo Kingsbury Machine Tools Limited

- Cell for machining airbus engine pylons 17th July 2018

- Portal mill for prototype tool and mould making 7th February 2018

- Manufacturing solutions reduce cost of production 6th February 2018

- Entering the additive manufacturing sector 2nd February 2018

-(1)ed.jpg)

Write a comment

No comments