Putnam plastics develops super-tri tubing, an advanced tri-layer technology

Putnam Plastics Corporation has developed an advanced tri-layer tubing technology that significantly improves tensile and burst strength, while reducing elongation. Super-Tri tubing is made with a proprietary extrusion process and aids in the prevention of wire lock-up in catheters where guidewires are used.

Standard tri-layer tubing, often used in PTCA (percutaneous transluminal coronary angioplasty) delivery systems, consists of three distinct polymer layers within one wall. Tri-layer construction typically involves a HDPE (high density polyethylene) inner liner for lubricity, a proprietary middle layer for bonding, and a polyamide outer layer which when combined, provides a unique combination of strength, trackability and bondability. Super-Tri tri-layer tubing technology utilizes the same material combination as traditional tri-layer tubingwhile providing superior performance characteristics.

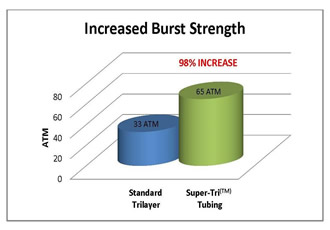

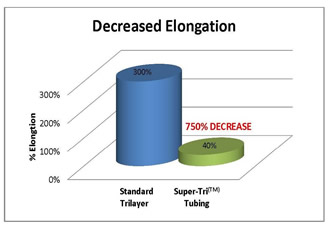

As the requirements for medical catheters and devices evolve, the need for innovative extrusion solutions has never been greater. For example, Super-Tri tubing assists in issues that have evolved from higher rated burst pressure balloons catheters. Compared to traditional tri-layer tubing, Super-Tri tubing has decreased elongation by 750% and increased burst strength by 98%. This makes this tubing technology ideal for balloon catheters requiring high pressure balloons. The significant reduction in the elongation and increased tensile strength considerably decrease the potential for guidewire lock-up. In addition, the Super-Tri tubing technology meets the same sizing, tolerances, and material configurations as traditional tri-layer tubing.

“Putnam’s new Super-Tri tubingtechnology has the ability to provide dramatically increased tensile strength while minimizing elongation,” saidBill Appling, Director of Engineering and Assembly, Putnam Plastics. “For example, a PTCA inner member where tri-layer tubing is most commonly used can now be produced with a 130% improvement in ultimate tensile strength, and 170% increase in tensile strength at yield. This product provides new options in the design of catheters for the next generation of devices where strength and size are critical.”

Similar articles

More from Putnam Plastics Corporation

- Laser machining capabilities includes ultra-short pulse technology 2nd February 2017

- Putnam plastics develops super-tri tubing, an advanced tri-layer technology 9th February 2016

- Putnam Plastics expands size range for medical peek tubing 30th October 2012

- Putnam Plastics expands product portfolio for variable flexibility medical catheter shafts 12th September 2012

Write a comment

No comments