PPE seals set the standard for the lowest trace metal levels

Precision Polymer Engineering unveiled new data demonstrating that its perfluoroelastomer sealing materials are still at the leading edge of technology and contain the lowest levels of trace metal elements in the industry. A total of 22 elastomer material samples, from several manufacturers, were tested for levels of 30 metal elements by an independent laboratory. The results reinforce PPE’s expertise and continued commitment to deliver the best high purity sealing solutions to the industry. The company will be showcasing its comprehensive offerings on its booth #1639 at Semicon West 2015, 14-16 July.

Device manufacturers in the semiconductor industry face numerous challenges on a day-to-day basis including particle and metallic ion contamination. As device dimensions shrink, there is a much greater potential for damage, which therefore requires lower levels of contamination. Even a small amount of metallic ion contaminant can change electrical characteristics and impact performance, or lead to reliability problems that could potentially go undetected until after the chips have been shipped and built into an electrical system.

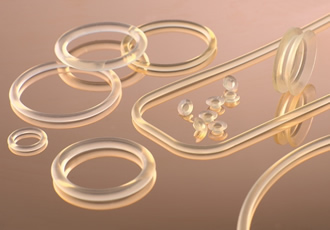

As device manufacturers make continuous efforts to avoid contamination, PPE is able to provide materials that support these challenges and offer elastomers with extremely low levels of trace metals. PPE has a long heritage of supplying optimized sealing solutions to the semiconductor manufacturing market. For many years PPE’s materials have provided high purity seals to the industry and its premium Perlast® grades, G67P and G100XT remain at the forefront of elastomer technology and the material of choice for many critical applications.

With manufacturing operations in the UK and USA, PPE supports its equipment manufacturer clients through the entire product lifecycle, from design stages all the way through to aftercare. Its tailored design capability integrated with expert knowledge of material properties, provides equipment manufacturers with access to application-specific customized sealing products and solutions. The main benefit is in allowing clients’ design engineers to focus on meeting targets and reducing the risk of product failure.

Commenting on this, Knut Beekmann, Market Manager for Semicon, PPE, said: “PPE is not just a provider of sealing materials, but can deliver customized engineered solutions for critical sealing applications in order to maximize seal integrity and longevity, helping semicon equipment manufacturers to reduce the cost of consumables and support the efforts against contamination. This data reflects that we still remain at the forefront of technology and are able to provide our customers with industry leading levels of cleanliness.”

PPE will be exhibiting at Semicon West 2015, San Francisco, USA from 14-16 July. Come and visit the team on booth #1639 to discuss how a sealing partnership can benefit your business.

Similar articles

More from Precision Polymer Engineering Ltd

- PPE seals set the standard for the lowest trace metal levels 7th July 2015

- Pump and Compressor Engineers Seals Guide 18th October 2010

- New Explosive Decompression perfluoroelastomer for pumps and valves 16th February 2010

- PPE Unveils Biofuel Sealing Solutions 5th February 2009

Write a comment

No comments