Precision milling machines use advance CNC solution

Advanced control solution for CNC milling machines that features a highly intuitive conversational style user interface, has been launched by NUM. Known as NUMmill, the CNC hardware and software provides a fully scalable control system and is supplied as a complete ‘off-the-shelf’ package.

NUMmill is designed specifically for CNC milling machine manufacturers and control retrofitters. It offers an extensive suite of canned cycles, ranging from simple centre drilling, boring and threading to pocket cycles and complex profile milling cycles. All with 3D simulation for pre-process verification. The package is suitable for a wide range of precision milling applications in markets as diverse as metal cutting, woodworking, plastic and high precision machining.

Based on NUM’s market-leading Flexium+ modular CNC platform, NUMmill is typically configured with three or four linear axes and a single rotary axis, though it easily scales to suit any size and type of milling machine application. All motorised axes are equipped with high performance brushless servo motors, controlled by NUM’s latest-generation NUMDrive X digital servo drives.

The NUMmill software features an exceptionally easy to understand graphical user interface which employs an interactive, conversational style dialogue to radically simplify machine operation, so simple, that end-users can operate machines without any prior knowledge of ISO code programming techniques.

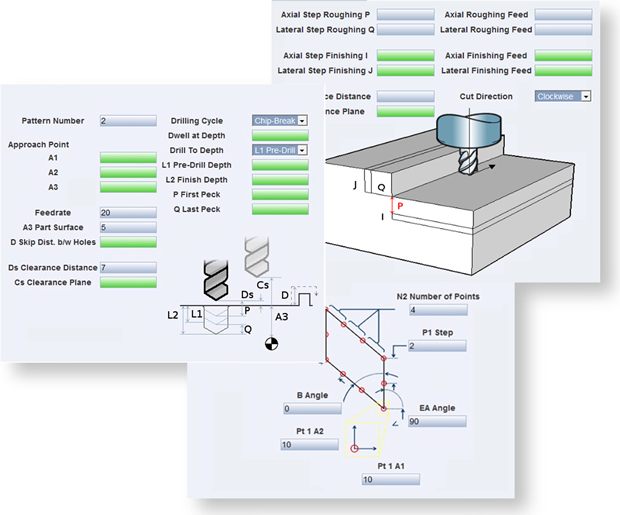

NUMmill Windows-based software provides graphical shop floor programming screens that depict the tool, the work piece and all associated setup data in a concise and unambiguous manner. The operator is prompted to fill in the appropriate data fields presented by the Human-Machine Interface (HMI), after which the machine control program is generated entirely automatically and then stored, ready for execution.

On-line help files and step-by-step video tutorials are included for ease of operation. This conversational style programming helps to save considerable development time, as well as significantly reducing the learning curve for new operators.

NUMmill is supplied as a complete, ready-to-run package that includes the Flexium+ CNC system, software, and a 19” touch-sensitive machine control panel, together with all necessary drives and motors. The system is also equipped with NUM’s MTConnect interface, which simplifies the integration of CNC machine tools with third party manufacturing software.

In addition to a large number of canned cycles, the NUMmill software provides functions for material removal of basic pockets; these can be defined as circular, oblong, reticular and square. The hole pattern definitions can use a wide variety of geometries, including Arc, Cover Patter, Drilling with Rotary Axis, Grid, Pitch Circle, Row and Single Points.

Milling operations can be performed on circular, oblong, rectangular and square pockets. The drilling cycles that can be performed on hole patterns include Centre Drill or Chamfer, Peck, Chip, Counter Bore, Tap, Ream-Feed Out, Bore-Dwell/Feed Out, Bore-Stop/Rapid Out, Thread Chase and Taper Threading.

Also providing measurement and probing cycles, the NUMmill system helps users meet precision and quality targets, as well as full 3D simulation with collision monitoring for pre-process verification. The Flexium+ architecture also offers machine designers, builders and retrofitters an easy means of implementing functional safety.

Similar articles

More from NUM (UK) Ltd

- Latest tool grinding software increases precision productivity 29th March 2018

- Graphical software brings shop floor programming simplicity 28th September 2017

- US machine control manufacturer uses CNC system for precision grinding 12th October 2016

- Wood machining centre uses 28-axis CNC system 12th October 2016

ed.jpg)

Write a comment

No comments