Latest tool grinding software increases precision productivity

A major new release of the renowned NUMROTO tool grinding software from NUM has just been launched. Offering numerous additional features and enhancements, Version 4.0 of the software is designed to increase the productivity of precision machine tools without the need for additional hardware.

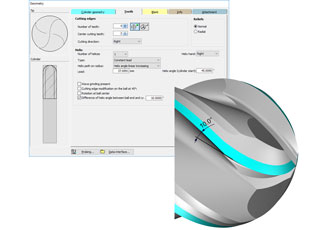

The ball nose and corner radius tools in NUMROTO now allow programming of a helix step on end mills. For the first time, it is now possible to program different helix angles for the end of the radius and the beginning of the cylindrical parts.

NUMROTO Draw, the software’s drawing and documentation tool, automatically processes the geometry data used for grinding a tool to generate a basic drawing. Many NUMROTO users choose to provide this drawing together with the finished, ground tool to their customers, to show standards compliance. The latest software release significantly extends this capability by automatically displaying the geometry of the grinding wheels and grinding wheel packages needed to make the tool in the drawing. Also all the important dimensions are automatically added to the grinding wheels. The time-saving benefits of this approach are considerable: a grinding wheel assembly drawing can be printed out for the machine operator to help speed setup without having to involve the design department, which is especially beneficial for companies handling numerous small production runs.

The 3D simulation facilities of NUMROTO Version 4.0 have also been further enhanced. Coolant holes in the 3D blank are displayed automatically, and users can now add DXF comparison profiles. There is a new measurement mode which provides comparator functionality, and the programmed feed rate can be displayed during the 3D simulation.

A new feature that is especially likely to appeal to users of high-end machine tools is support for adaptive grinding. By continuously monitoring the dynamic performance of the grinding spindle, the software enables the feed rate to be optimized automatically – without the need to install any additional hardware. This offers a very cost-effective means of increasing the productivity of certain grinding processes.

First launched in 1987, NUMROTO software has become the preferred choice for many of the world’s leading manufacturers of machines for the production and re-sharpening of tools such as end-mills, drills, step drills, form cutters and many others. It is currently used on 5,500 machines worldwide.

Compared to most competitive products on the market, the software provides a much more direct and efficient path between tool design and manufacture.

Similar articles

More from NUM (UK) Ltd

- Latest tool grinding software increases precision productivity 29th March 2018

- Graphical software brings shop floor programming simplicity 28th September 2017

- US machine control manufacturer uses CNC system for precision grinding 12th October 2016

- Wood machining centre uses 28-axis CNC system 12th October 2016

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments