NUM (UK) Ltd

Address:

Unit 3 Fairfield Court

Seven Stars Industrial Estate

Wheler Road

Coventry

CV3 4LJ

United Kingdom

Seven Stars Industrial Estate

Wheler Road

Coventry

CV3 4LJ

United Kingdom

Phone: 0871 750 4020

Web: http://www.num.com

NUM (UK) Ltd articles

Displaying 1 - 19 of 19

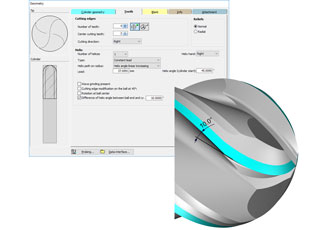

Latest tool grinding software increases precision productivity

A major new release of the renowned NUMROTO tool grinding software from NUM has just been launched. Offering numerous additional features and enhancements, Version 4.0 of the software is designed to increase the productivity of precision machine tools without the need for additional hardware.

29th March 2018

US machine control manufacturer uses CNC system for precision grinding

US machine tool control specialist CNC Onestop is being helped with advanced CNC systems from NUM, to maintain competitive market edge through the use of precise positioning techniques. Based in Ohio, but also operating in Toronto, CNC Onestop is a CNC engineering company that works in full CNC, motor and drive retrofits for machine tools, as well as machine rebuilds and troubleshooting.

12th October 2016

Wood machining centre uses 28-axis CNC system

A precision wood machining machine based on a 28-axis CNC system from NUM has been launched by Krüsi Maschinenbau. The new MC15 provides very high quality wood machining capabilities and can be equipped with up to 28 axes and a maximum of six machining heads, each of which can be fitted with four machine tools.

12th October 2016

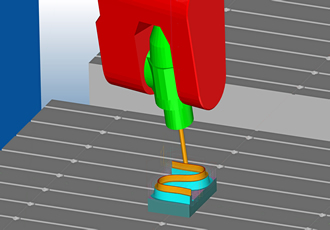

Precision milling machines use advance CNC solution

Advanced control solution for CNC milling machines that features a highly intuitive conversational style user interface, has been launched by NUM. Known as NUMmill, the CNC hardware and software provides a fully scalable control system and is supplied as a complete ‘off-the-shelf’ package.

14th September 2016

Num to demonstrate end-mill grinding software innovation at Grindtec 2016

NUM will be demonstrating an innovative new development to its renowned NUMROTO tool grinding software at GrindTec 2016. The company is launching a suite of enhancements for the package, including new gash out-X and flute-X facilities that pave the way for next-generation complex geometry tools.

28th January 2016

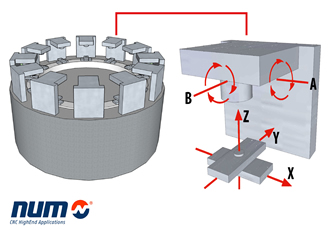

CNC Axis sharing innovation paves the way for more versatile machine tools

NUM has launched an innovative new CNC axis sharing facility that will enable designers to create machine tools of unprecedented versatility and productivity. It provides a very flexible and efficient means of controlling a high number of functionally interrelated groups of motion axes, by using advanced dynamic resource allocation techniques to share control across multiple CNC kernels. Typical applications include multi-station production centres and rotary transfer machines with complex multi-role axis control requirements.

3rd November 2015

Customised CNC upgrade simplifies railcar axle grinding

A comprehensive upgrade of classic high power centreless grinding machine tools is helping a leading railcar axle manufacturer to greatly simplify precision grinding operations on axle forgings. A key element of the project – which has been managed by APeC Integration Services – is the retrofit of customised CNC control based on NUM’s powerful Flexium platform.

12th August 2015

CNC Systems Gain MTconnect Interface To Enhance Interoperability Of Machine Tools And Manufacturing Software

NUM has developed a new communications interface option for its CNC systems that fully complies with the open MTConnect interoperability standard. Known as NUMConnect, the interface can be fitted to new or existing systems and simplifies the integration of CNC machine tools with third party manufacturing management software. It enables users to implement powerful productivity-enhancing real-time data collection and retrieval facilities for production monitoring and analysis purposes.

15th January 2015

First US showing of innovative two-channel CNC system for machine tools with up to five axes

NUM is showing its new two-channel CNC kernel for the first time in the US at IMTS. Designed specifically for developers of small to medium sized machine tools with four or five axes, the Flexium+ 8 CNC provides an exceptionally cost-effective control solution that in many cases eliminates the need for a second CNC kernel. NUM is also launching a new version of its 3D simulation software which now includes kinematic equations to support advanced 5-axis machining applications.

18th September 2014

CNC developments to be showcased at IMTS 2014

At IMTS 2014, NUM will showcase its latest developments in machine tool CNC hardware and software technology. Highlights will include a highly cost-effective dual channel CNC kernel for designers of small to medium size machines with up to five axes, a functional safety architecture that can easily be scaled to suit any type of machine, and new grinding software for complex geometry tools.

22nd August 2014

Scalable Functional Safety Architecture Addresses Needs Of Specialist CNC Machine Builders

NUM has released a sophisticated system-wide functional safety architecture for its CNC system, providing an exceptionally scalable solution that can be applied very easily to almost any type of machine tool – regardless of complexity or number of axes. Known as NUMSafe, it includes a dedicated safety PLC, safe input and output modules, and digital servo drives with built-in safe motion monitoring. It is compatible with NUM's new-generation Flexium+ CNC platform.

5th February 2013

Innovative Servometers Slash CNC Machine Building Costs

NUM announces two new brushless servomotor ranges for CNC machinery applications which provide major savings by eliminating the need for a separate encoder cable. Machine builders can now use a single drive-to-motor cable for each motion axis, thereby reducing cabling, speeding installation/commissioning, and improving system performance. NUM estimates that for a typical high-end CNC machine installation involving 20 metre cable lengths, the new technology can reduce total motor cabling costs by as much as 20 percent per axis.

11th October 2012

NUM at EMO - The World of Metalworking, Hannover 19-24 September 2011, Stand C25

NUM is currently celebrating 50 years of technical innovation. Its technology underpins many of the world's most successful specialist machine builders, and today the company views continued innovation and customisation of CNC as crucial to the maintenance of a healthy machine tool sector.

21st September 2011

WIND TURBINE GEAR PRODUCTION ACCELERATED BY CNC REFURBISHMENT OF GEAR SHAPER - linear actuator instead of ‘nodding’ cam enables gear profile changeovers in minutes instead of hours

Advanced gear shaping software and motion control hardware from NUM has been used to bring an old manually-controlled gear shaper machine up to modern day control standards. The five-axis Stanko machine is now controlled by a NUM Axium Power CNC system, using electronic gearbox techniques to synchronise the rotary cutter, gear blank and stroking axes. It also incorporates an innovative programmable replacement for the stroking axis, which reduces product changeover time from hours to minutes - significantly improving productivity.

14th June 2011

Innovative CNC-based precision water jet cutting machine provides 1 micron accuracy

Precision machine building company MDC Max Daetwyler AG and specialist water jet company Waterjet AG, in collaboration with NUM, have developed an innovative CNC-based water jet cutting machine capable of cutting materials to within ±1 micron – which is 20 times more accurate than competitive machines. The new WOMAJET/microWATERJET machine is also extremely efficient – it consumes considerably less water and abrasives than traditional systems – and looks set to open up entirely new application areas for this form of materials processing technology.

6th September 2010

Novel new tool head design for cutting machinery slashes the cost of migrating to 3D movement

NUM is launching an innovative ready-integrated pan-and-tilt tool head solution for sophisticated plasma, laser and waterjet cutting machinery applications. Called NUMcut, it provides a very simple means of extending the capability of machinery from 2D to 3D applications, with precise multi-axis interpolation.

9th October 2009

Advanced CNC simulation software helps to produce innovative new range of twist drills

CNC multi-axis grinding machines using NUM’s NUMROTOplus 3D simulation and control software are helping Miller Präzisionswerkzeuge GmbH to manufacture a new series of high-performance MAPAL-brand solid carbide twist drills. The new drill tools employ complex optimised profiles to accelerate cutting speeds.

4th September 2009