Offering 'loads' more at EMO

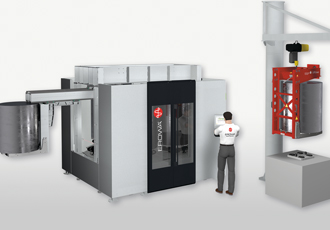

The new EROWA Robot Easy 800 will be on show at this year’s EMO Hannover 2019 show, and you can find the automated system that opens up new horizons in machine loading located in Hall 12 on Stand E83. With the new robot parts, which measure up to 850x1,000mm with a maximum weight of 800kg, reliably can be delivered to the machine tools working envelope.

With experience based around this technology, EROWA knows that maintaining high productivity of an automated system also requires that the ergonomics need to be taken into account. A central setup station with a swivel crane facilitates the operator’s daily work considerably. Rotatable magazine plates simplify setup and preparation. Pre-centring facilitates pallet positioning with crane and LiftGear.

The stable transfer axis of the robot has a large travel of 3,200mm, and it can load machine tables between 765 1,200mm. It means there is sufficient space for an operator to manually set up any work at the machine tool’s table, if there is a need to ‘break into’ the production run or some special fixturing is required. While the magazine has a 6,400kg loading capacity within a compact 9m2 footprint.

All the data required for the production cell is available at a glance, including worklist, magazine loading, tool availability and priorities, via the EROWA process control system. This makes it easy and intuitive to use the Robot Easy 800, even though the size of the parts can be formidable.

Also at EMO the EROWA process control system JMS 4.0 plays a major role in detailed production planning. It forms a large part of the functionalities that are described as ‘Smart factory’.

With machines reporting their status in real-time, the in-process control with automatic feedback allows production to run at the highest efficiency levels. Flexible interfaces to upstream and downstream systems are a matter of course. Workpiece pallets and electrode holders can be identified at any time using RFID chips.

Important advantages arise for the user: It is always clear which workpiece is at which point in the process at what time. In addition, there is an unequalled clear statement on the productivity of the integrated systems. The keyword is OEE (Overall Equipment Effectiveness) and creating transparency to optimise existing processes if necessary.

On the OEE Dashboard users can see at a glance what the efficiency status is like. Various screens offer a clear and structured overview for all production cells, or individually down to minute detail for a single machine.

Fully automatic cells can be monitored with CCTV cameras. Various camera settings are displayed directly in the JMS 4.0 Process Control System. All necessary information is available to the machine operator on one screen. Further views can be called up quickly via sliders.

Live Alarm - Regardless of the users’ geographical location, the JMS 4.0 Alarming app informs all relevant staff about the status of the JMS 4.0 production cell. With push notifications received as soon as a machine or robot receives critical alarms or orders are no longer available.

The EROWA JMS 4.0 software provides a clear overview. It connects all data and controls the entire manufacturing process. With modular software bundles, it can also be expanded at any time as required. Providing manufacturing efficiency that can be scaled to fit almost any application, from REM Systems Erowa.

Similar articles

More from REM Systems

- EROWA's smart factory gets even bigger 1st June 2020

- Machine tool automation – does one size fit all? 14th August 2019

- Offering 'loads' more at EMO 5th August 2019

- Companies partner to set the longest robotic cell in aerospace 26th September 2016

ed.jpg)

Write a comment

No comments