EROWA's smart factory gets even bigger

For over 30 years EROWA has been providing smart factory automation to the various global manufacturing industry sectors and at this year’s MACH 2020 exhibition, which is now rescheduled to January 2021, the company was due to highlight its Flexible Manufacturing Concept using automation as part of a factory installation. With robot systems capable of handling small workpieces from a few kilos to large parts up to 4 tonnes, EROWA is shining the spotlight on its ability to ‘Go Large and Heavy’.

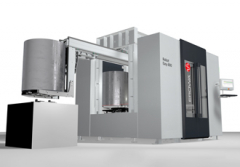

Offering around-the-clock running for machine tools producing heavier components, up to 4,000kg, the EROWA LoadMaster Compact range provides reliability and robust operation. Each LoadMaster can cater for a variety of component sizes set to match the spread of workpieces that customers’ machine shops have to tackle.

The LoadMaster Compact highlights how easy it is to load raw material billets, cast or forged components into the multitiered storage system ready for unattended milling and turning. Finish machined parts can be removed via the ergonomic workstations or returned to the layered racking for retrieval when required.

The new LoadMaster range builds on the company's renowned reputation for precision and quality to offer automatic loading and unloading of large workpieces. With the return on investment that customers have come to expect. Thanks to the ingenious kinetic system with very limited space requirement. With the 360° swivel function, any position in the magazine and on the machine tables can be reliably reached.

The magazines are of vertical design; the storage positions are arranged over two, three or four levels, saving on space and cost. Each level is optimally configured for typical workpiece sizes. The magazine modules can be combined in series. So, there are no limits on the number of units that can be connected, and the total rail length depends on the number of machines and their positioning.

With walk-in or accessible via sliding doors the setup stations are integral components of the LoadMaster production lines. Versions are available with lifting unit, with rotating and tilting table, or with indexing table. The setup positions are also accessible via overhead crane.

EROWA’s ‘Pilot’ control software makes schedule control, tool and job management very straightforward. It assists the operator in the daily production flow, with clear displays of system status.

Mixed pallet sizes in a production line allow optimal use of the available space and for systems with different pallet sizes the ‘MultiFork’ gripper is an efficient alternative to changing individual grippers. The gripper width smoothly adapts to different pallet dimensions. Solid, robust technology for large workpieces.

For workshops where space is at a premium the EROWA Easy 800 keeps it tight. Launched at EMO last year, the automation specialist’s rationale for the Easy 800 is intended to support the efficient machining of larger components. Capable of deploying heavier workpieces on larger pallets, but within a minimal footprint the Easy 800 offers a significant increase in the size of the raw material or part finished components that can be accommodated, up to 850mm diameter and up to 1,000mm in height with 6 stations.

“The impetus from the manufacturing industry has been for larger, more complex machine tools and now these can be fully automated with the Easy 800,” explained Managing Director, Ian Holbeche. “Using the EROWA ‘Flexible Manufacturing Concept’ (FMC) customers equipped with an automation system can typically increase productivity by a factor of five using various manufacturing technology, including die sinking EDM, multi axis milling and turning, as well as measurement and inspection.”

EROWA’s goal of increasing the productivity of machine tools using its FMC philosophy based on its automation systems, and the four steps to follow to achieve the maximum number of working hours (up to an incredible 8,760 hours per year) from any machine.

As Holbeche pointed out: “Maximising the number of hours on your existing machine tools before you invest in your next machine can saving you time and money. EROWA has the ability to retrofit automation systems to existing standalone machine tools and even manufacturing cells, so the advantages and benefits are available to just about any manufacturing business.”

Similar articles

More from REM Systems

- EROWA's smart factory gets even bigger 1st June 2020

- Machine tool automation – does one size fit all? 14th August 2019

- Offering 'loads' more at EMO 5th August 2019

- Companies partner to set the longest robotic cell in aerospace 26th September 2016

ed.jpg)

Write a comment

No comments