Dynamatic-Oldland Aerospace have DMG MORI Giga Milling Centre

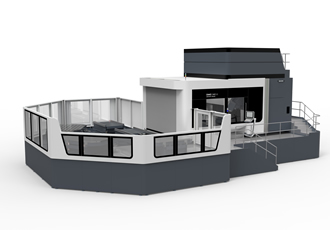

Dynamatic-Oldland Aerospace is installing a DMG MORI DMC 340 U RS4 Giga Milling Centre in a new purpose built unit at its Swindon facility, the first machine of this type in the private sector in the UK. With a capacity of 3,400 mm in X, 3,400 mm in Y and 2,000 mm in Z this machine has four pallets, is capable of handling workpieces of 16 tons, has a rapid traverse rate of 60m/min and a tool magazine holding 180 tools each of which can weigh up to 30 kg. James Tucker, Managing Director of Dynamatic Limited UK says, “The versatility of this machine in the manufacture of complex parts in aluminium alloy, steel and titanium alloy fits well into our existing machine pool. The machine, expected to be delivered this June, will help us to serve our existing and new customers and deliver larger and much more challenging parts.”

Started in the 1970’s, the group company Dynamatic Technologies has companies specialising in the hydraulics, automotive and aerospace industry sectors. For the aerospace industry, Dynamatic-Oldland Aerospace™ has four manufacturing plants Bristol and Swindon in the UK and Bangalore and Nashik in India. The company supplies aero structures and assemblies for the fuselage and wings directly to aerospace primes including Airbus, Boeing, Bell Helicopter and Hindustan Aeronautics Limited. It is also an Airbus Centre of Excellence for Flap Track Beams and is the only company in India to be a single source supplier. Dynamatic produces two variants one for the A320, manufacturing around 50 sets per month and the other for the A330 at eight sets per month.

Ajay Gururaj, Project Manager at Dynamatic-Oldland Aerospace says, “We have a very good relationship with DMG MORI. The quality of the German manufactured machines is exceptional and the combination of precision and high speed they deliver is a capability which is difficult to find. Reliability is good with hardly any downtime, whilst both service and spares are delivered very efficiently. Local support is available in the UK and in Bangalore where we can have access to telephone support or, if necessary, an engineer can be on-site in two hours. Because of the cost of the DMC 340 U RS4 the support we get will be a key factor as we will need to keep the machine running.”

For Dynamatic-Oldland Aerospace the size of the machine and the number of pallets was an important factor. The large bed size enables it to machine larger parts, while the four pallets make it possible to run the machine unmanned. With the four pallet arrangement on the DMC 340 U RS4, parts can be set while the machine is running and complete parts can be produced in one cycle cutting one side of the component in one fixture and the other side in a second fixture. Additionally, the arrangement gives more flexibility allowing unmanned machining overnight and the ability to choose the order in which parts are run. If the company had chosen a single or dual pallet machine, two to four hour setup times would have resulted in significant idle time and much less flexibility.

Already the company has sufficient work to fill the capacity of the new DMC 340 U RS4, where parts are cut to a tolerance of 50-60 microns, well within the capabilities of the machine. However it also sees an opportunity to broaden its horizons with engine and landing gear parts where tolerances are 15-20 microns, which are also easily achievable.

Ajay Gururaj adds, “We get involved in projects at an early stage with a 9-18 month cycle of industrialising and optimising for cost effective manufacture. During this phase we develop special tools and strategies and identify machines, for delivery in 9-12 months, necessary to solve complex problems. Because of the scale of our operation we are able to plan well ahead as we are dedicated to longer term contracts from a minimum of five years to the life of the product. We have a strategy for investing in capital equipment and manufacturing in the UK as the cost of money is low and we are close to our market here.”

Steve Finn, Managing Director of DMG MORI UK says, “The quality of our machines and the after sales service we can offer are clearly crucial to the high value manufacturing ethos of Dynamatic-Oldland Aerospace. Investing in the DMC 340 U RS4 will give the company a very significant advantage in its market place enabling it to offer a unique service to its customers. We are delighted that it has chosen to work closely with us both in the UK and India and we look forward to continuing and expanding our collaboration.”

Similar articles

More from DMG MORI UK

- Rebuilding business for long term success 12th August 2019

- Actively shaping the digital future at EMO 8th August 2019

- DMG MORI technology helps achieve OEE for ejector company 28th February 2018

- Compact machining centre suits aerospace and mechanical applications 10th January 2018

ed.jpg)

Write a comment

No comments