Centres built for 5-axis machining of light materials

Their rigid construction, wide range of spindle speed and power options, and low-mass moving elements means the Sahos 5-axis machining centres from the Czech Republic are suitable for producing components from light materials. Aluminium, model board, plastics including varieties reinforced with carbon fibre and glass fibre, and composites and such as bonded honeycomb and multi-layer structures can all be machined accurately and with a high degree of efficiency.

At Advanced Engineering 2016, this product programme will be the main theme on the stand of the manufacturer’s sole agent in the UK and Ireland, Asquith Butler, along with the message that the entire machine range is currently being rebranded under the name Blue Ray.

Paul Hinchliffe, managing director of Asquith Butler said: “Machines in the Sahos/Blue Ray portfolio offer production solutions in many sectors, notably aerospace, motorsport and automotive, while larger models in the range are frequently used to manufacture parts in transportation, boatbuilding and even theatre and film set construction.”

Hinchliffe continued: “The whole point of these machines is efficient milling and drilling of light materials at elevated speeds to close tolerances. Repeated light cuts taken at high feed rates replace deeper, slower cuts on traditional metal cutting machining centres.”

“The benefits are that a heavy, expensive machine structure is not needed, spindle load is lighter and surface finish on components is better, as the highly dynamic motions and low chip load mean that there is less susceptibility to chatter.”

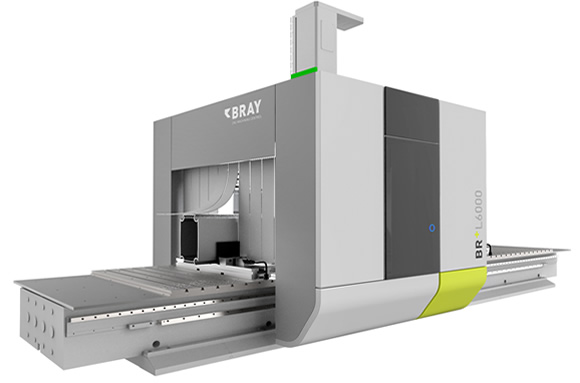

BRaL 5-axis machining centre

Launched in 2015 at EMO, Sahos/Blue Ray’s BRaL series of gantry-type, compact, 5-axis machining centres will be introduced to the UK at Advanced Engineering 2016. Designed with a generous X-axis for producing large components from aluminium profiles up to 30m long, it is especially well suited to processing parts in the rail, commercial vehicle and building industries.

Modular construction makes it possible for a customer to specify a machine that exactly suits specific requirements, assisted by the availability of a wealth of accessories. Moreover, the machine can be adapted quickly to suit the manufacture of a different range of components.

Fourth and fifth CNC axes (A and C) are incorporated into the liquid-cooled, high precision swivel head carrying the spindle. The head is equipped as standard with pneumatic Heidenhain iTNC530 HSCI or Siemens Sinumerik 840D SL.

BRaM machining centre

Another highlight of the Asquith Butler stand will be the smaller, high speed BRaM 5-axis, gantry-type machining centre, which was also launched last year. The fully-enclosed machine has rapid axis movements, with linear acceleration at 5m/s2 up to 80m/min in X, Y and Z, with the theoretical possibility of raising the speed to 120m/min. Different sizes of machine can be specified, based on an X-axis of either 3,000 or 4,000mm, a Y-axis of 1,500 or 2,200mm and a choice of 800, 1,200 and 1,600mm in Z.

Access to the working area of the BRaM is unrivalled due to the twin folding door design, allowing easy loading of workpieces from the front by lift truck, while overhead loading by crane is equally easy. With cutting of composites in mind, the guarding is comprehensive and includes the option of a roller shutter covering the whole of the ceiling.

Provision has been made for dust extraction from the entire machining area and from the point of cutting. For applications involving extensive machining of aluminium alloys, a swarf conveyor can be integrated into the machine.

Hinchliffe continued: “We have had a lot of success selling Sahos/Blue Ray machines in the UK over the past couple of years, since we were appointed the sole agent.”

“There are now 20 machines operating across the UK in diverse industries, including for pattern and mould making and F1 modelling, as well as in the aerospace and automotive supply chains."

“What is especially pleasing is that some customers have come back to buy a second and third Sahos/Blue Ray machine, which is a testament to their high quality,” Hinchliffe added.

“Our engineers have been factory-trained in the Czech Republic to service the machines and to provide customers with top-level applications and technical support.”

He concluded that there is considerable synergy between Sahos/Blue Ray and Asquith Butler, which manufactures a range of large-capacity, travelling-gantry, vertical machining centres and mill-turn centres at its factory in Brighouse, West Yorkshire.

One potential area of collaboration is the ability of Asquith Butler’s engineers to retrofit a rotary table to a Sahos/Blue Ray machining centre. Another is the British manufacturer’s expertise in carrying out complete mechanical and control system retrofits as well as machine relocations, with eight major projects currently in progress.

Similar articles

More from Advanced Engineering (Middleton) Ltd

- Advanced Engineering to make a 2017 return with focus on Industry 4.0 10th February 2017

- Centres built for 5-axis machining of light materials 26th September 2016

- UK’s largest dedicated advanced engineering event launches new hub 9th August 2016

- Advanced Engineering 2016 announces new partnership 16th May 2016

ed.jpg)

Write a comment

No comments