Big things can come in small packages

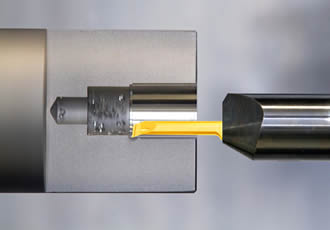

Now available in a new high-performance version for small jobs such as, internal grooving, chamfering, threading, broaching, facing and parting-off exotic alloys and steels, is the 105 Supermini system manufactured by Horn, which includes those that are structurally inhomogeneous. User benefits include improved productivity and significantly increased tool life.

Featuring a new coating, substrate and microgeometry, the carbide inserts are designed to machine bores in demanding, highly alloyed materials from 0.2-6.8mm diameter. Standard lengths are from five times diameter at the smaller end of the range to a maximum of 35mm.

The Supermini system offers more than 1,500 insert types for a host of different applications. Right and left-hand versions can be used in one standard Horn Supermini toolholder, available with or without internal cooling.

During development of the tool, a performance increase of 30% was achieved solely by modifying the substrate and keeping the coating and insert microgeometry the same. Horn then found that a sharper cutting edge resulted in higher metal removal rate and less cutting pressure. Although mechanical stress on the edge was elevated, the tougher substrate was able to cope.

A new coating system was devised, tailored to the combination of the tough substrate and the more durable cutting edge. It allows a denser layer of TiAlN (titanium-aluminium-nitride) with a more homogeneous structure to be deposited with excellent adhesion and improved smoothness. The enhanced anti-friction properties mean that less heat is transferred to the tool, so the cutting edge is exposed to lower thermal stress.

High-performance 105 Supermini tool life comparisons with existing substrates and coatings were carried out by Horn and results showed that using the new EG35 grade on cobalt-chrome, a popular alloy used in the medical sector, tool life was increased by as much as 60%.

In the case of carbon steel, tool life more than doubled and when tests were carried out machining tool steel, the tool life increase compared to competitors’ inserts was even greater.

Similar articles

More from Horn Cutting Tools

- High level of accuracy with side milling cutter 19th November 2018

- Grooving and parting off tool for smaller lathes 20th September 2018

- Adjustable side milling cutter for grooving 20th August 2018

- Innovative gear milling system developed for DMG MORI 7th July 2017

ed.jpg)

Write a comment

No comments