Machining

Displaying 211 - 220 of 460

Single source supply reduces costs for machine builders

In order to find assembly efficiencies and reduce costs, the automotive industry and other global manufacturing businesses have long supported the mantra of a reduced supplier base. The real benefits are in a drastically reduced expenditure on development and a faster time-to-market for new products.

28th February 2017

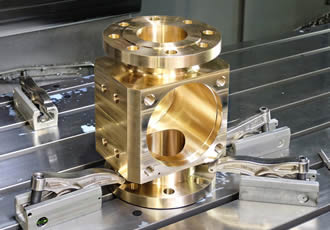

Sheffield subcontractor takes the big capacity route to machining

Sheffield contract machining firm Ian Cocker Engineering, for the later part of its career, has relied on almost only Hurco vertical machining centres to produce prismatic components, mainly for the oil and gas sector and frequently from difficult materials such as stainless steel and Inconel.

24th February 2017

Cutting up your carrots, courgettes and cucumbers

When working in automation within the food industry precision is key. For food industry automation company Stelram Engineering no challenge is ever too great. So when the company had to develop a machine that would cut and trim carrots, ready to deal with the peak demand in the festive season, its engineers were not in the least daunted. Calling on the knowledge of water-jet cutting technology, it swiftly produced an efficient and cost-effective machine that delivered a convenient and hygienic solution.

24th February 2017

Cutters designed for milling titanium

A new, extensive range of solid carbide milling cutters have been launched by Horn, which are designed specifically for machining titanium alloys such as Ti6Al4V. The programme comprises cutters with diameters from 2-20mm, available in four and five flute geometries with a cutting edge length of 2xD and 3xD.

24th February 2017

Programme provides true measure of a machine's movement

OffLine 2 Running (OL2R) is an optional programme and special precision bracket set that is available for the Fixturlaser NXA Pro & Ultimate. This option allows the shaft aligner to accurately measure vertical AND horizontal changes of machines from a static (OffLine) position to a running position.

Author: Tom Shelton, Vibralign

22nd February 2017

Carbon dioxide laser power source on the rise

Fibre laser technology has taken over from the CO2 laser power source when cutting sheet metal and plate into components of simple or complex shape. David Larcombe, Managing Director of Bystronic, revealed that since August 2015 the company has not sold a single CO2 laser cutting machine in Britain or Ireland.

21st February 2017

Latest milling adaptors include higher metal removal rates

Designed to offer improved damping characteristics are the latest Silent Tools milling adaptors from Sandvik Coromant. These advanced adaptors have been developed in direct response to the need for greater metal removal rates and reduced vibration wherever long, slender milling tools are deployed.

20th February 2017

CLS sectional mobile valve helps articulating boom mowers hold steady

Designing and building heavy duty roadside management equipment, Tri-Tech Manufacturing also includes boom arm mowing attachments for tractors. The company’s Mow-MasterTM products are used to mow hillsides and trim overhanging tree branches, requiring heavy duty construction to withstand the stresses of use on rugged terrain.

17th February 2017