Programme provides true measure of a machine's movement

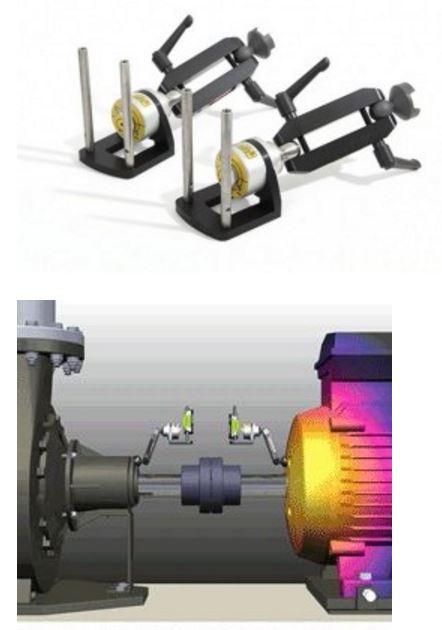

OffLine 2 Running (OL2R) is an optional programme and special precision bracket set that is available for the Fixturlaser NXA Pro & Ultimate. This option allows the shaft aligner to accurately measure vertical AND horizontal changes of machines from a static (OffLine) position to a running position.

Author: Tom Shelton, Vibralign

This allows for very precise targeting of rotating machinery during a shaft alignment while the machines are OffLine. When a precision shaft alignment is performed, the goal is to have the rotational centerlines of the machines co-linear when in a running state. Due to dynamic forces such as thermal growth or shrinkage, piping influences, and/or process pressures, the position of the machine’s rotational centerlines can change from the aligned static position to the operational position.

If known changes to a machine are going to occur from a cold static position to a running position the machines are aligned based on the given targets such as thermal offsets. When targets are used, they must be calculated or supplied to the mechanic from any number of sources, usually a plant engineer or reliability specialist, but where do they get this information?

Usually from manufacturer supplied data or calculations of some type which are typically only for changes in the vertical plane. When using the OL2R programme and brackets you get REAL data regarding position changes for the specific machine(s) in question. Not only will you see any vertical changes in position, but you will also discover horizontal changes that you may not be aware are occurring. This will definitely impact the reliability of this piece of equipment and isn’t improving equipment reliability what we are trying to achieve?

The way the OL2R system works is very simple:

1st – Mount the OL2R brackets to the stationary and moveable elements of your machine. Make sure that you are able to replace coupling guards without disturbing the brackets.

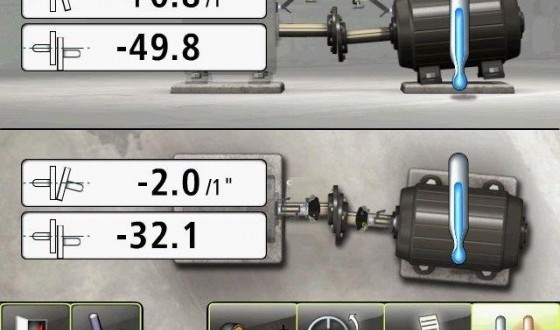

2nd – Take the 'Live' hot reading with the machines at full running state, up to temperature and under common load and save it. The 'Hot' position will be displayed. Note: this is not an indication of the actual hot alignment, but simply a known 'Hot' position. (You can also start by taking the 'Cold' readings first).

3rd – After allowing the machines to cool to ambient temperature take the cold readings and save it. The 'Cold' position will be displayed. Note: This is not an indication of the actual cold alignment, but simply a known 'Cold' position.

4th – Once these measurements have been saved, the NXA will compare the Cold minus Hot readings and display the REAL Targets needed to compensate for dynamic changes from Offline 2 running. The targets are then saved for future shaft alignments. At this point you can align the machine as indicated by the procedure. Simply touch the coupling icon and align the machine. You will now have a true precision shaft alignment.

This is a much abbreviated explanation of the OL2R process. With training and practice this process can yield very positive results for your company or customers.

Similar articles

More from Vibralign

- Programme provides true measure of a machine's movement 22nd February 2017

ed.jpg)

Write a comment

No comments