Machining

Displaying 11 - 20 of 460

igus goes to great lengths with expansion of hybrid chains series

The world’s first hybrid chain is now available in two new sizes - designed by igus for construction machinery and lifting equipment. These YE hybrid chains, made of polymer and steel, are 50% lighter than conventional steel chains and can safely move large hydraulic hoses and high fill weights vertically on both mobile crane platforms and construction machinery.

16th February 2021

The generator sweet spot

In cycling, sweet spot training involves placing the body under sustained stress, but not so much stress that it cannot be held for a long duration. It can be defined in relation to a percentage of the cyclist’s functional threshold power and aims to increase the cyclist’s fitness, while getting the most out of their time. Here Clinton Noble, Diesel Generator Sales Manager at Finning UK & Ireland power systems, explains how generators, like cyclists, have a sweet spot that can mean operators get the best out of their investment.

9th December 2020

Steering into the future for mobile machinery

Parker Hannifin has launched a mobile directional control valve that can be used in a Steer-by-Wire system for earth-moving equipment and other types of mobile machinery. This high performance single fault tolerant valve is designed to support the ongoing evolution and trend for electrification of vehicles in this market.

17th November 2020

How to reduce cabinet clutter in food production

Food manufacturers can achieve flexible production lines at minimal labour costs, by adopting automation without cabinets. Stephen Hayes, Managing Director of Beckhoff Automation UK, explains how food processing operations can be reconfigured with machines that can be transported and moved, more easily and faster than traditional machinery.

5th November 2020

Are temperatures rising too high for UK power?

In August 2020, roadside recovery provider, Green Flag predicted a surge in breakdowns due to the UK’s hot weather - 15 drivers were predicted to break down every minute over the period of the heatwave. As well as creating issues with tyre pressure and chemicals in car batteries, hot weather can cause engines to overheat. Facilities managers need confidence that the same won’t happen to the engines in their back-up generators.

29th October 2020

The need for speed: blue FDA compliant knife edge rollers

igus have designed and manufactured a new high performance polymer well suited for the growing demands of the food production sector. The new iglidur A250 tribo-polymer, designed and manufactured by igus, is the a new polymer material in the company’s product range to meet the strict hygiene requirements of the Food and Drug Administration (FDA) and EU 10/2011 regulations, while also meeting the growing demand for higher conveyor belt speeds.

29th October 2020

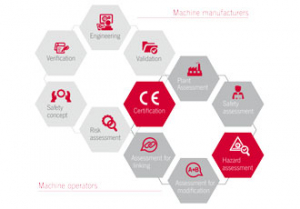

The importance of machinery safety in current times

UK manufacturers are advised to ensure robust safety checks, as well as competency assessments for staff, are carried out, before restarting machinery safety that has been left idle due to lockdown restrictions or social distancing because of the coronavirus pandemic, suggests Euchner, a specialist in safety engineering.

14th October 2020

CNC investment to meet demand for precision engineering

Swansea-based hygienic engineering company, Axium Process has invested in two new Doosan CNC machines to meet increased demand for high quality precision engineering. This capital investment means Axium Process, a manufacturer of bespoke pharmaceutical processing equipment, can support the sector with higher volumes of precision engineered components that are designed in-house.

12th October 2020

How Sandvik has encouraged steel circularity

Extractive industries such as mining are responsible for 50% of global carbon dioxide (CO2) emissions. However, recycling steel from mining equipment could make all the difference. Here, Anders Åkesson, QM EHS Manager, Crushing & Screening at Sandvik Mining & Rock Technology (SMRT), Sandvik Group, explains how Sandvik has encouraged steel circularity in the mining industry.

3rd September 2020

The intricacies of restricted access drilling

Most people don't link geotechnical drilling to an urban setting, but sometimes, the connection needs to be made. There are plenty of scenarios where a regular rig won’t work, making restricted access drilling the perfect option. It’s natural to think of busy towns and cities when considering a site with restricted access, but this form of drilling is frequently used in more rural settings too. If it’s difficult to access the site, then a specialist, restricted access rig is the answer.

28th July 2020