Machining

Displaying 151 - 160 of 460

Blurring the lines between OEM and aftermarket parts

The acceptance of replacement parts suppliers for engines used in the power generation market has evolved significantly over the past few decades. The consistent quality, availability, coverage and warranty of products from branded aftermarket suppliers now are increasingly rivaling those of their OEM counterparts.

3rd July 2017

Newly set up machining centre fits into tight space

A subcontract machining firm has been set up near Coventry to undertake small batch manufacture and project work that other subcontractors and OEMs may consider a nuisance, as they interrupt production. Called Overstone Engineering, the company is owned by Richard Dunn, who has 40 years’ subcontract engineering experience.

30th June 2017

Rein it in! 1,000 bogie saddles repaired for freight operator

In the rail industry, one of the most important aspects to maintaining high safety standard is regular inspection and maintenance of the rolling stock and tracks. For one freight operator this has included the overhaul of 250 coal wagons that needed new wear plates installing onto the bogie saddles, a task that Sulzer has completed as part of its on-going work in the rail sector. Keeping rail freight wagons in good running order requires the rolling stock to undergo general repairs every ten years or after a predetermined distance in work.

29th June 2017

Deuce vices deliver flexibility and security

Supplying vices and fixtures from 5th Axis for over five years, YMT Technologies has also been installing hundreds of its products in the UK market. Manufactured at 5th Axis’ headquarters in San Diego, the designs for its workholding products originated from its own requirement for fixtures for efficient and economic manufacture of the wide range of aerospace, military, medical and commercial products it produced. Now, 5th Axis is a major supplier of workholding equipment in the USA.

27th June 2017

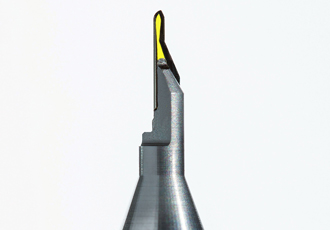

Rapid laser texturing on mould surfaces

A new, 5-axis CNC machine has been introduced by DMG MORI for laser ablation of geometrically defined textures into the surface of moulds, such as those that produce plastic car fittings or electronic housings. The machining process is more environmentally friendly than conventional etching and offers a greater freedom of design, while at the same time ensuring a high level of repeatability. It is also capable of creating filigree cavities without the need to manufacture electrodes.

13th June 2017

Mouldmaker chooses bridge-type machining centre

As precision mould manufacturer and injection moulding specialist BM Injection was looking to replace an ageing, 3-axis, vertical-spindle machining centre of C-frame design back in the autumn of 2016, the company had three main requirements for the new machine. It needed to be of bridge construction for improved rigidity and have a nominal one-metre X-axis to provide extra capacity. It also had to be able to compensate for fluctuations in temperature on the shop floor.

9th June 2017

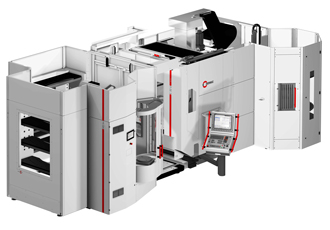

Low-cost automated workpiece handling system launched

Manufactured by the German company, Hermle, three- to five-axis CNC machining centres can be equipped with a new, automated workpiece handling system that requires low capital investment. UK and Ireland agent, Geo Kingsbury, said that the equipment can be factory fitted or retrofitted to machines already in use.

9th June 2017

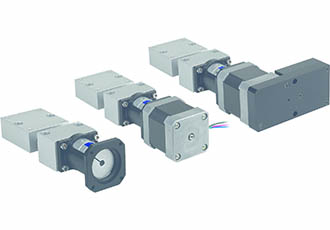

Motorised positioning tables enter the UK

norelem UK has added a range of motorised positioning tables to its BIG GREEN BOOK, a complete reference guide for design engineers, mechanical engineers, machine builders and toolmakers. Its electric powered, low noise, and low maintenance motorised positioning tables are an alternative to manual versions for bringing components, stops, limit switches, grippers and even cameras into position to a hundredth of a millimetre.

5th June 2017

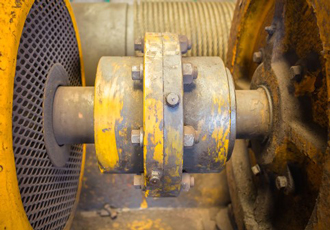

Roughing in before precision shaft alignment

The reason for roughing in precision laser shaft alignment has little to do with how accurately the lasers/sensors measure. It has nothing to do with how big the laser detector is, or how sensitive the detectors are, or how fast they are. Roughing in isn’t simply to 'get it close'. It is to minimise errors due to the following:

2nd June 2017