Machining

Displaying 161 - 170 of 460

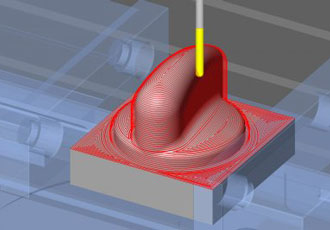

Latest version of ESPRIT delivers smarter and faster machining

As ESPRIT becomes smarter it enables faster programming, and CAM industry innovator DP Technology has announced the release of ESPRIT 2017, the latest version of its pioneering flagship product. ESPRIT 2017 delivers a smarter, simpler, faster machining process with expert toolpath, streamlined user control, and accelerated processing power.

23rd May 2017

Lathes automated without specialist knowledge

A mobile robotic cell has been introduced by machine tool manufacturer DMG MORI to automate its CNC turning centres. Called Robo2Go, it loads raw billets from a tray and unloads machined components automatically. The unit can be relocated easily by pallet truck to serve up to four different lathes sequentially on a shop floor.

22nd May 2017

Electro hydraulic control machine outlines core competencies

Intelligent factories and smart energy topped off with market shifts in industry 4.0 are the factors behind companies being challenged to offer the seamless integration of multiple different technologies and disciplines. Within this field Eaton’s complementary electric and hydraulic expertise can bring easier and faster solutions.

19th May 2017

New selection of insert tools are diamond-tipped

The latest addition to Horn’s products ranges include diamond-tipped Supermini and Mini tools with internal cooling directly to the cutting edge for boring, profiling and grooving. The new ranges of insert tooling are well suited to machining aluminium, sintered carbide, ceramics and plastics.

18th May 2017

Weight transmitters used for agricultural produce handling machinery

The automated BOXFILR system specifically for handling vegetable produce such as potatoes, carrots and onions is manufactured by Netherlands based agricultural machinery specialist Van Hees. During harvest time for farm use, and as an all-year-round support for distribution storage and transportation, the system includes conveyor delivery, filling, emptying and crate stacking operations with very high efficiency thanks to several modules that perform specific tasks.

17th May 2017

Automatic fusion splicer still provides ROI for customers

As the world’s first fully automatic fusion splicer, Fujikura Europe’s 70S provides ROI for customers and an increased productivity via reduced splice cycles. Not only is the 70S believed to be the most ergonomic, fastest and durable technology of its kind, but its longevity has proved it is 'built to last', meaning that customers could still be using the same 70S they purchase today more than ten years from now. It only requires four operational steps per splice and reduces splicing time to just six seconds.

16th May 2017

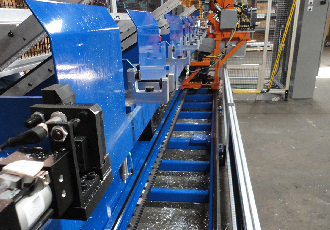

Compact cold mill ordered to double cold strip capacity

The Pakistani cold strip producer, International Steels Limited (ISL) earlier this year placed an order with SMS group for the full-line supply of a twin-stand CCM (Compact Cold Mill) in four-high design. In the course of the systematic expansion of its production facilities, ISL has decided to use the flexible and reliable SMS group technology. Since 2011, the Pakistani cold strip producer, located in Karachi, has been operating a reversing cold mill from SMS group.

10th May 2017

Bringing precision engineering to DLR repair project

Sulzer has been contracted to inspect and repair the bogie frames of 76 rail vehicles over the next two years, as part of the ongoing maintenance and refurbishment project of the Docklands Light Railway (DLR). The project requires considerable attention to detail, especially with regard to the quality processes and documentation, as well as a streamlined welding and machining operation capable of completing each vehicle on time.

9th May 2017

Integrating single servo axis into high-speed rotobroacher

Michigan-based company Lumco Manufacturing, designs, builds and integrates automation and special machine equipment for the automotive, agricultural, gas and oil, energy and aerospace industries. Recently, Lumco custom-built a single-spindle multi-station aluminium drilling and rotobroaching machine to be used to manufacture components of a construction industry aluminium brake.

8th May 2017

Cycle times cut through faster feeds and speeds

Dicker Precision Components, at its East Sussex factory of subcontract machinists, has a Biglia twin-turret, twin-spindle CNC turning centre supplied by Whitehouse Machine Tools, which has streamlined the production of a family of aluminium switch cover assemblies. The savings are so great that the cycle time for producing one part of the assembly has been halved while the other part is produced in a little over one-third of the time.

8th May 2017