Sealed connection system on display at EDS 2017

At this year’s Engineering Design Show, taking place 18th to 19th October, Molex (stand K18) will showcase its multi-dimensional approach in meeting the most demanding needs of the design industry. The company will have on display a diverse representation of its products that support a wide-range of applications in a variety of connector sizes and shapes. These products provide design engineers with the ultimate in flexible, scalable solutions that deliver speed and reliability for next-gen system architectures.

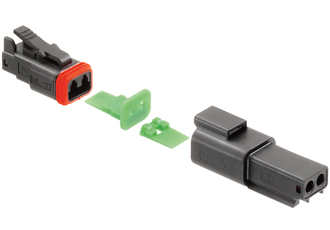

Molex takes the collaborative approach to ensure a smooth design cycle as well as create diverse connector solutions for a broad range of applications: whether for transferring power, signals, data or media. One such development, on display at the show, is the ML-XT sealed connection system. Molex has employed sealing technology and advanced manufacturing techniques to breathe new life into the equivalent mated system used in commercial vehicles that was first introduced almost 30 years ago.

When developing the ML-XT system, particular attention was made on enhancing the sealing integrity over the standard system to help prevent electrical failures in the field. Rated IP69K and J2030 power-wash capable, the ML-XT features a one-piece plug housing and seal design, which is permanently bonded using cutting edge, two-shot LSR (liquid silicone rubber) moulding technology.

Molex will also be exhibiting its PowerLife wireless power coils with NuCurrent technology, solution. A logical next-step in connectivity, wireless power requires the right technologies to achieve optimal device charging; traditional wire-wound coils require wider electrical tolerances and can be bulky or difficult to integrate, especially into products that require thin designs or are intended for use in harsh environments. High-efficiency PowerLife wireless power coils with NuCurrent technology withstand vibration, heat and humidity, and transmit power through air, wood, or any non-metallic surface.

Downloads

Similar articles

More from Molex Incorporated

- Collaboration to provide Industry 4.0 solutions 28th November 2018

- Powerful environmental tool offers robust data measurement 9th October 2017

- Sealed connection system on display at EDS 2017 4th October 2017

- High-speed Impel data cable solution supports Open19 initiative 22nd March 2017

Write a comment

No comments