HANNOVER MESSE Robotics Award won by fleXstructures

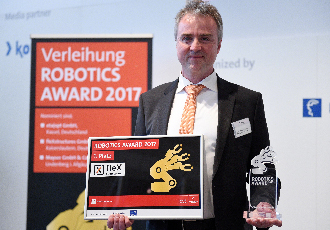

There has been a lot going on at HANNOVER MESSE this week, and it has recently been announced that the winner of the Robotics Award 2017 is fleXstructures, a company founded back in 2011. The joint prize from the organisers of HANNOVER MESSE and the Konradin-Verlag publishing house, was given at the official ceremony held on Tuesday 25th, and the CEO of fleXstructures, Oliver Hermanns was delighted to receive the prize in honor of its ‘IPS ROBOT OPTIMIZATION’ software solution.

Second place was taken by Mayser (Lindenberg, Germany) with eta|opt (Kassel, Germany) coming in at third place.

The expert jury is annually faced with the challenge of choosing the top innovation from an array of advanced solutions for applications in robot-assisted industrial automation or mobile robots and autonomous systems. One important prerequisite is that the solutions submitted may not yet have been presented to the public, or else they need to represent a significant enhancement over existing solutions. Furthermore, they must be market-ready or already deployed in real-world industrial trials. Other criteria applied by the jury are economic and technological potential as well as industrial and social benefit.

The winning entry this year, the ‘IPS ROBOT OPTIMIZATION’ was described as an entry which illustrated the vast potential of advanced simulation technology for industrial use. This solution is targeted primarily at helping automotive manufacturers to gain a competitive edge by programming and commissioning their robot cells faster and more flexibly.

By simulating millions of potential robot path combinations, ‘IPS ROBOT OPTIMIZATION’ coordinates movement paths and sequences across multiple robots so as to maximise efficiency and avoid collisions. The simulations also optimise movement paths to ensure maximum service life for the flexible hoses and lines attached to the robots.

Second place went to Mayserfor its ultrasonic machine safety sensor system designed to safeguard personnel in collaborative human/robot environments. The product has been tested and certified for personnel safety applications in machine environments.

The ultrasonic sensors generate an elliptical ultrasonic field which can accurately gauge distances of up to 200cm and issue warnings by detecting persons or objects at distances of up to 250cm. The product can be used for cobot tool and workpiece safety, and for protecting people from sharp or rotating objects.

And finally, third place went to eta|optfor its vacuum generator for industrial robotic handling applications. The device doesn’t require any compressed air system, and instead uses a bellows vacuum pump.

A piston driven by an electromechanical linear actuator compresses and releases a bellows which is connected to a hose. The other end of the hose can be connected to any standard vacuum gripper attachment. When the bellows is released, it generates a vacuum inside the hose and all the way down to the gripper.

HANNOVER MESSE is taking place from 24th-28th April in Hannover, Germany.

Similar articles

More from Deutsche Messe

- Engineer Powerwoman 2020 – the search is on! 14th January 2020

- Industrial Transformation MEXICO announced 6th September 2018

- 2018 brings Engineer Powerwoman again to Hannover Messe 5th January 2018

- Industry 4.0 reaches next stage for HANNOVER MESSE 2018 20th September 2017

Write a comment

No comments