Servo motor system is robust and low-cost

A combined motor and resolver claimed to be robust while also lower in cost, smaller in size and lighter in weight than other servo motor systems, has been launched by QuickSilver. This is because the sensor in the Mosolver is based on a polymide sensor coil, therefore, unlike other systems, the environmental limits of the servo aculator are limited by the motor rather than the sensor.

With encoder systems, the cleanliness of the disk, sensor and spacing between them are all critical to success. Grease displaced from a bearing or dust may disrupt the operation of the sensor. Resolvers with their feedback are more robust, but typically expensive. Both encoders and resolvers must be aligned to their motors for proper commutation phasing.

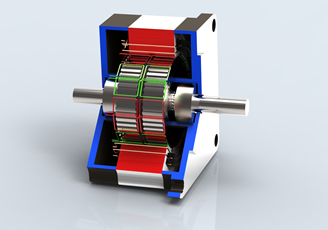

In the Mosolver the sensor coils are built on a passive polyimide flex circuit, affixed within the motor stator structure in the process of motor assembly. The standard polyimide sensor material is rated from -80 to +180°C, with other formulations (substrate and adhesive systems) available with wide working temperature ranges from -269 to +400°C. When combined with a motor with similar ratings, the Mosolver is capable of operating in a wide variety of harsh environments. With the sensor encapsulated within the motor structure, the motor servo system is the same size as the motor itself and does not require additional housings to protect the feedback element as would be required for a resolver or encoder, thus saving weight as well as space. As the sensor does not incorporate active devices nor moving elements, it has a high degree of robustness. The sensing method is AC based and is not subject to DC temperature drifts nor ambient magnetic fields as are hall effect devices. As the sensor is built into the same structure as the motor, no alignment/phasing adjustment is needed.

The Mosolver sense coils are embedded in between the stator teeth of the motor. These coils detect the flux variation caused by the stator ripple current normally associated with a PWM drive. The variation in current caused by the ripple current causes a flux variation, even when the motor is stationary. The flux, including the pulsing variation, is divided between different sections of the sense coil according to the tooth overlap between the rotor teeth and the stator teeth, the overlap varying with rotor position. When properly sampled in synchronism with the PWM drive, the sensor coil produces sine and cosine information.

The sine and cosine information is decoded into 640 positions for each of the 50 electrical cycles per revolution, resulting in 32,000 positions per revolution. The sine and cosine information is also used for motor commutation without the need for a startup 'wiggle' eliminating the startup transient. The Mosolver position feedback is maintained at zero speed, eliminating the drift associated with sensorless methods when maintaining position. Due to the construction, which shares the magnetic structure of the motor for both motion and sensing, the sensor is inherently aligned. Electronics to support the sensor consist of an amplifier for each of the two phases, and two ADCs already present on the controlling DSP.

The Mosolver may be applied to differing motor sizes, allowing for high resolution even in smaller motor frames where matching encoders are either expensive or are larger than the motor itself. The system is also available in product format and for licensing of speciality motors.

Similar articles

More from QuickSilver Controls, Inc.

- Servo motor system is robust and low-cost 7th July 2014

- NEMA 23 Servo Motor with Improved Efficiency and Power 13th October 2009

- Servo Motor Controller QCI-D2-IGK 5th February 2009

- CiA 402-CANopen Drives and Motion Control Profile 16th January 2009

Write a comment

No comments