Gearbox range meets the needs of high speed drives as standard

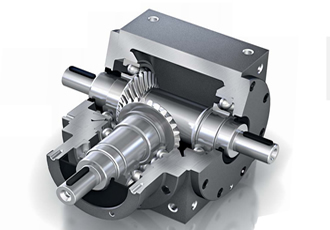

Developed to meet the special needs of high speed applications, the MS-Graessner PowerGear HS range of high speed, bevel gearboxes can be used in transfer lines, manufacturing automation systems and test beds for high performance vehicle drive trains.

Available in the UK through Drive Lines Technologies, the PowerGear HS has been designed specifically for the requirements of demanding installations: it is not a development from or adaption of another gearbox, but was designed from the ground up using the decades of engineering expertise of the MS-Graessner R&D team.

Each individual component was specifically developed and designed to meet the demands experienced during operation at the highest speeds.

Ian Carr of Drive Lines explained: “These gearboxes are likely to be used in duties where they will be required to run at high speeds for extended periods. In such applications it is sensible to assume that there will be a considerable amount of external friction, which will lead to heat build-up.”

For this reason the high speed units are built with a larger body than the rest of the Graessner PowerGear range, so that they can accommodate more oil and thus cope with the heat. This leads to the need for high-quality seals. The body is cast iron for strength, integrity and thermal stability.

“The whole idea is that users can buy an off the shelf unit for their high speed drive needs. One that they do not have to customise, but which instead can be mounted and used straight out of the box,” said Carr.

One of the key design features is that the gearing is optimised for higher speeds and maximum tooth contact pattern to spread the load and ensure smooth running over a long working life. The Gleason gear tooth profile is used throughout the range. This ensures a generous contact pattern throughout the tooth to tooth engagement cycle so that the load is uniformly spread across the tooth, allowing high speeds and high torque performance. A friction-locked fit between shaft and bevel gear ensures fretting-free torque transfer.

The PowerGear HS range is available with four gear sets from S90 to S170 and in gear ratios of 1:1, 1.5:1 and 2:1. Options include flange, solid, or hollow shaft versions and standard or reduced backlash options. Maximum input speed for the range is 8500rpm. Their 98% efficiency ensures low power input requirements. In use motor mounting is usually via a coupling and lantern.

The design’s high performance capabilities, including low backlash, high accuracy transmission and excellent thermal performance means they are suitable for the most dynamic servo drive-train applications. They are also suitable for use as a pre-stage for coaxial gearboxes.

Optional features are also available for the high speed range. These include cooling ribs with or without a fan or an oil circulation system for additional oil cooling capabilities as well as extended output hollow shaft for shrink discs and mounting feet. Stainless steel versions are also available for hygiene aware applications, as are customised designs if required.

Similar articles

More from Drive Lines Technologies Ltd

- Linear drive solutions offer independent and precise sub-systems 11th October 2017

- High performance bevel gearbox range extended with new size 18th September 2017

- Mechanical Backlash: How much is too much? 5th September 2017

- Performance and longevity improved through dynamic balance 7th August 2017

Write a comment

No comments