Drive Lines Technologies Ltd

Address:

45 Murdock Road

Bedford

MK41 7PQ

United Kingdom

Bedford

MK41 7PQ

United Kingdom

Drive Lines Technologies Ltd articles

Displaying 1 - 20 of 24

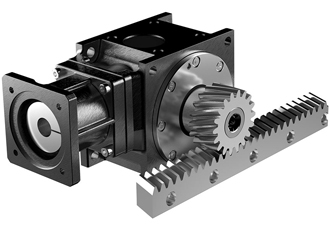

Linear drive solutions offer independent and precise sub-systems

Provider of power transmission solutions, Drive Lines Technologies, now offers a complete linear drive solution incorporating rack and pinion mechanisms that complement the MS-Graessner ranges of precision servo gearboxes, including KS-TwinGear, DynaGear, DynaGear DG and DynaGear PL systems. These solutions include low-backlash precision gearboxes, shrink-fit direct shaft mounted pinion gears and precision toothed racks with dedicated lubrication systems.

11th October 2017

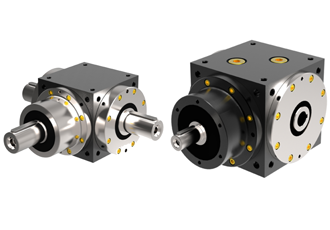

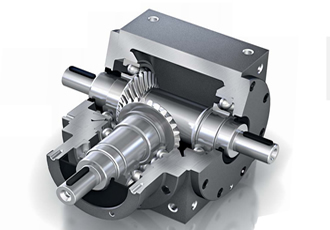

High performance bevel gearbox range extended with new size

The Graessner PowerGear P range of bevel gearboxes has had another size added to the series, the P-65, which is available from Drive Lines. Sized at 65mm cubed it is expected to prove very popular in a wide range of applications, such as for use with screw jacks to create vertical lifting and lowering mechanisms.

18th September 2017

Mechanical Backlash: How much is too much?

When you hear the word backlash, it is a natural reaction to assume it is a bad thing which needs to be designed out of every engineered system. The reality isn’t so simple, as Ian Carr, Managing Director of Drive Line Technologies, explains: “There are times when backlash is unacceptable; other times when it does not really have any effect at all; and sometimes when controlled backlash is actually a benefit.”

5th September 2017

Performance and longevity improved through dynamic balance

It is crucial for high speed precision motion systems to be dynamically balanced; otherwise they will vibrate in use, lose precision, suffer excessive wear and fail prematurely. Here, Ian Carr of Drive Lines Technologies in Bedford reviews procedures and techniques for balancing high speed precision couplings.

7th August 2017

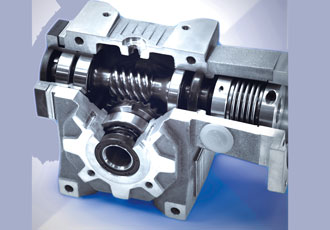

Space saving servo gearheads reduce backlash

Demanding servo applications in areas such as packaging, materials handling, machine tools and robotics, as well as general automation need the precision worm gearbox from Drive Lines Technologies in their Servoplan range. Promising maintenance-free, long life operation with a highly compact design, the SWG gearhead can be specified with precision of better than 1arcminute (arcmin).

31st July 2017

Synchronised jacking system aids precision tilting on research flumes

Representing one of today’s biggest ecological challenges is water; it covers everything from flood prevention to resource protection. Tilting flumes are increasingly providing engineers with a key tool in the research of hydraulics and sedimentology. The latest products from Armfield offer the greatest levels of versatility, thanks to an automated jacking system supplied by Drives Lines Technologies.

21st July 2017

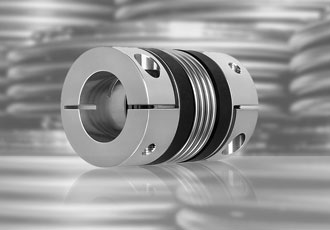

The overlooked heroes of the drive train

There is skill, expertise and insight required when matching a coupling to its duties in any given drive train, the coupling for example may be required to accommodate misalignment, ensure safety, absorb shock loads and perform other functions too. Ian Carr at specialist engineers, Drive Lines, explained the features and benefits that different industrial couplings from the R+W range offer, and suggests where to use them.

19th July 2017

Combined bearings and profiles for lifting applications

A reliable, efficient and cost effective lifting system is essential for heavy duty fabrications and automation projects can become a mine field. With so many different solutions available often the time invested in finding the most suitable solution for an application is devoted to the type of screw jack and motor used. However, if you start to look at some of the ‘lesser’ components then the cost of the entire application can be reduced, whilst maintaining a trustworthy and economical system.

15th June 2017

Getting straight to the point with linear transmission engineering

In areas such as automated assembly packaging and robotics, the need for linear motion is increasingly common, but it is also common in diverse applications such as retail displays, sports equipment and many other areas. This has led to a plethora of different linear technologies, and finding your way through this can be daunting. Matt Jones, a linear motion specialist at Drive Lines Technologies, offers a quick guide through the basics.

2nd May 2017

Giant motor and pump parts lead to a lean manufacture

Drive Lines provides components used in the construction of portable workstations, also known as Crusers at Hayward Tyler, which are patent pending. The Crusers were developed by continuous improvement engineer Oliver Buhlinger with the aim of increasing the mobility of the movement of products weighing up to 40 tonnes to improve work flow efficiency and safety.

13th April 2017

Lifting Manchester Cathedral’s dais to new heights

Embarking on a development project to enhance the experience for worshippers and visitors, Manchester Cathedral saw one of the important aspects of the project to improve on the heating facilities in the Cathedral. This involved the installation of ground source heat pumps and an under-floor heating system. The decision was made to use the opportunity to replace the existing dais with an electromechanical alternative which could be raised and lowered on demand – courtesy of a lifting system supplied by Drive Lines.

1st March 2017

Gearboxes safe to use with food technology equipment

A food safe version of the popular PowerGear spiral bevel gearbox manufactured by MS Graessner is the latest development from Drive Lines. It has a gear housing coated with Duralloy-TDC (Thin Dense Chrome), a material which Zurich-based test bureau Labor Veritas has verified as safe for use with food technology equipment.

24th January 2017

Precision drive developed for aircraft wing spar former

After winning a contract to manufacture a large hot drape former, for a major aerospace company in Russia, AIC Group then turned to Drive Lines for help with the drive systems. The two companies had worked on similar projects together previously, so between them had considerable expert knowledge of this laminating technology.

19th January 2017

Screw jacks play pivotal role in transporting giant wind turbines

Providing a larger than ever percentage of the world’s electrical power is offshore wind turbines, and as a result there is an increasing need to get the giant nacelles that house all the machinery from factory to dockside for shipment out to the wind farm safely and efficiently. Playing a vital role in this difficult task are the high capacity screw jacks manufactured by Grob Antriebstechnik and available in the UK through Drive Lines Technologies.

18th January 2017

New quality management standard attained in UK

One of the first UK mechanical power transmission companies, Drive Lines Technologies has been approved to the new, revised ISO9001:2015 standard for quality management. Organisations that are approved to ISO 9001:2008 have been granted three years to attain the new standard. However, Drive Lines saw the revisions as an opportunity to review its quality management and ensure that it remains ahead of the curve within its industry.

21st December 2016

Amsterdam Airport Tulip shop show stopper

Doubling the revenues at the House of Tulips flower shop at Amsterdam’s Schiphol Airport, is the reconstruction its recently undergone, to become a ‘flying house’ that rises up three metres or more to provide total access to the merchandise from all sides. The glasshouse lifts up in the morning at the start of business, and then is lowered again at night to provide absolute security.

1st November 2016