Simufact Releases New Product Versions - Simufact.forming 11 and Simufact.welding 3.1

6th August 2012

Source:

Simufact Engineering gmbh

The Hamburg-based software company Simufact Engineering now offers new versions of its simulation software Simufact.forming and Simufact.welding. Providing more functionality for a broader scope of application while offering a simplified usability - that's the credo of the new software versions that are employed for the design and optimization of manufacturing techniques in metal processing.

With the new Simufact software releases, companies aiming to link various production processes in the process chain (from semi-finished material to finished component) have come closer to their goal of an integrated, cross-process approach in the simulation of entire process chains.

Simufact simulation solutions cover all essential production processes from forging to cold massive forming, rolling, sheet metal forming, mechanical joining, heat treatment, and welding. Also, standard interfaces allow customers a fast and reliable integration of Simufact software in their CAD/CAE environments.

A major step forward is Simufact’s integration of material data in the simulation of forming and joining processes: Simufact.forming 11 and Simufact.welding 3.1 not only offer a multitude of new, experimental material data; they also provide access to high quality analytical material data, thus ensuring accurate simulation results.

Simufact.forming 11 – professional forming simulation

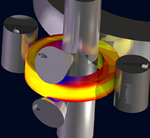

Simufact.forming is an established simulation solution for forming and joining processes. The software release Simufact.forming 11 includes new modules for open die forging and ring rolling. Application-specific functionalities such as fully automated processing of a complete pass schedule in open die or radial forging, and the consideration of the manufacturer’s kinematic concepts in ring rolling, help the user to model and simulate all possible processes and conditions of these production processes.

Thanks to new possibilities in result-dependant, force and path controlled processing as well as an optional, method-related calculation of the structural transformation during forging, these new special modules have become indispensable tools for companies that use ring rolling and open die forging.

Release 11 is particularly interesting for joining experts, since it takes adhesives and high speed effects into consideration, which are gaining more importance in modern joining technology.

By offering improved possibilities for networking and evaluation, Simufact.forming 11 eases the engineer’s daily work in tool and process development. The feature “optimization” allows the comfortable testing of process options and ensures substantial time savings for the definition of the best process design. Highlights include the flexible description of thermo-physical boundary and initial conditions, and the automated reporting in pre- and post-processing.

The efficient simulation of realistic heat-treatment processes provides for more flexibility and realism in mapping the process chain – before, during, and after the forming process.

Simufact.welding 3.1 – more than welding simulation

Simufact.welding 3.1 enables the simulation of various welding methods. Cutting edge solver technology and a user friendly overall concept allow for an effective calculation of welding sequences and a realistic prediction of component distortion, also taking into account microstructural transformations.

The coupling of Simufact.welding with Simufact.forming is a new functionality linking different process chains. Thus, processes taking place before or after welding can be efficiently integrated in the numerical approach. Easy data transfer allows for consideration of the forming history and the strength analyses of the simulated welding seams.

The calculation of phase transformation and phase volume fractions, as well as the automatic mapping of weld filler metals complement the new features. Simufact.welding 3.1 provides the user with a simple and comfortable modelling of more complex welding seams, even the simulation of multi-layer welding is now possible. Last but not least, the new release offers an improved calculation of contacts for process related gap formation during the welding process.

Simufact simulation solutions cover all essential production processes from forging to cold massive forming, rolling, sheet metal forming, mechanical joining, heat treatment, and welding. Also, standard interfaces allow customers a fast and reliable integration of Simufact software in their CAD/CAE environments.

A major step forward is Simufact’s integration of material data in the simulation of forming and joining processes: Simufact.forming 11 and Simufact.welding 3.1 not only offer a multitude of new, experimental material data; they also provide access to high quality analytical material data, thus ensuring accurate simulation results.

Simufact.forming 11 – professional forming simulation

Simufact.forming is an established simulation solution for forming and joining processes. The software release Simufact.forming 11 includes new modules for open die forging and ring rolling. Application-specific functionalities such as fully automated processing of a complete pass schedule in open die or radial forging, and the consideration of the manufacturer’s kinematic concepts in ring rolling, help the user to model and simulate all possible processes and conditions of these production processes.

Thanks to new possibilities in result-dependant, force and path controlled processing as well as an optional, method-related calculation of the structural transformation during forging, these new special modules have become indispensable tools for companies that use ring rolling and open die forging.

Release 11 is particularly interesting for joining experts, since it takes adhesives and high speed effects into consideration, which are gaining more importance in modern joining technology.

By offering improved possibilities for networking and evaluation, Simufact.forming 11 eases the engineer’s daily work in tool and process development. The feature “optimization” allows the comfortable testing of process options and ensures substantial time savings for the definition of the best process design. Highlights include the flexible description of thermo-physical boundary and initial conditions, and the automated reporting in pre- and post-processing.

The efficient simulation of realistic heat-treatment processes provides for more flexibility and realism in mapping the process chain – before, during, and after the forming process.

Simufact.welding 3.1 – more than welding simulation

Simufact.welding 3.1 enables the simulation of various welding methods. Cutting edge solver technology and a user friendly overall concept allow for an effective calculation of welding sequences and a realistic prediction of component distortion, also taking into account microstructural transformations.

The coupling of Simufact.welding with Simufact.forming is a new functionality linking different process chains. Thus, processes taking place before or after welding can be efficiently integrated in the numerical approach. Easy data transfer allows for consideration of the forming history and the strength analyses of the simulated welding seams.

The calculation of phase transformation and phase volume fractions, as well as the automatic mapping of weld filler metals complement the new features. Simufact.welding 3.1 provides the user with a simple and comfortable modelling of more complex welding seams, even the simulation of multi-layer welding is now possible. Last but not least, the new release offers an improved calculation of contacts for process related gap formation during the welding process.

Similar articles

More from Simufact Engineering gmbh

- Simufact Engineering and Universiti Teknologi MARA Shah Alam in Malaysia agree on cooperation in research and training 28th February 2013

- Simufact Engineering has founded subsidiary in India 22nd February 2013

- Simufact and Schuler SMG enter technology partnership 18th September 2012

- Simufact Releases New Product Versions - Simufact.forming 11 and Simufact.welding 3.1 6th August 2012

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments