SEPAC expands options for spring engaged brakes

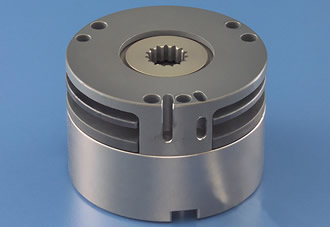

SEPAC regularly modifies its product designs to fit specific OEM application requirements. Customisation is a core competency at SEPAC where the engineering team frequently walks OEMs through the process of a custom solution, from rapid prototyping to calibration and controlled production. The Spring Engaged Brake (SEB) showcases the range of options the company makes available to OEMs.

The SEB series is spring engaged and electromagnetically released for use dry or in oil depending on the friction material used. Robust friction materials are available with higher torque density for both static and dynamic engagement.

Multiple disc configurations are available when higher torque is needed in a smaller package. OEMs can also select custom coatings, enclosures and materials for conditions as varied as water, oil, salt spray, high pressure, low/high temperature and even a vacuum environment such as space.

The SEB series offers custom voltages, as well as fully potted coils (standard or vacuum potted), dual coils and step down power designs. Special integrated drive hubs and specialty enclosures with sensors or manual release are additional design options.

Similar articles

More from SEPAC

- Higher torque delivered in SFTC Series 21st October 2016

- SEPAC expands options for spring engaged brakes 7th October 2016

- Thin spring brake 70% thinner for OEM applications 22nd July 2016

technology at Jacobs Vehicle Systems.JPG)

Write a comment

No comments