Sulzer Ltd

Address:

Zürcherstrasse 14

8401 Winterthur

Switzerland

8401 Winterthur

Switzerland

Sulzer Ltd articles

Displaying 21 - 40 of 93

Long live the wind turbine!

Achieving an online availability of about 98%, wind turbines give operators approximately one week in the year when planned maintenance can be completed. It is essential to use this time efficiently, concentrating on the most important issues, which can be identified using preventative maintenance techniques. Jason Horton, Regional Operations Director (South) at Sulzer, looks at the benefits of creating a partnership with a specialist maintenance provider in terms of improved lifespan and reliability of wind turbines.

5th January 2018

Setting new standards for maintenance and repairs

Many industries are reassessing the way in which they tackle maintenance issues in response to increasing pressure to reduce costs and optimise performance. Sulzer’s Glasgow facility has been quick to expand the capabilities and expertise of its staff to ensure additional benefits for customers and help meet these demands.

22nd November 2017

Ensuring productivity for EDF Energy nuclear site

EDF Energy, which operates eight nuclear power stations in the UK, has awarded a contract for availability (CFA) to Sulzer for the maintenance and continued support of the boiler feed pumps at the Heysham 2 plant, near Morecambe in the North West of England. The contract provides a fixed cost to ensure optimum availability of these critical assets, thus maximising the reliability of supply from the generating plant.

31st August 2017

Electro-mechanical services minimise operating costs

It is a skilled task to maintain the reliability of generators and large motors, and one that is central to the productivity of many industries. Most large businesses using this specialist equipment have to choose between engaging a number of original equipment manufacturers (OEMs) or selecting an independent service provider (ISP). The outcome of this decision can affect running costs as well as the efficiency and productivity of the company.

15th August 2017

Power generation pumps on show at Asia Power Week 2017

Speakers and exhibitors will showcase the latest innovations and discuss solutions to the challenges facing the power industry as Asia Power Week returns to Thailand this year. As an independent repair specialist and pump manufacturer, Sulzer will be highlighting its pumps and systems for power generation as well as the range of services on offer to operators of gas turbines and other rotating equipment. 2017 sees the 25th anniversary of the Asia Power Week, with more than 8,000 industry professionals expected to attend.

3rd August 2017

Sulzer finds engineering talent with summer intern programme

Investment is an important process for any business. Investment in new facilities and manufacturing tools keeps the company modern, while investment in R&D helps to keep it at the top of its game within the industry. The Sulzer summer intern programme finds some of the most promising young engineers and gives them the experience required to jump start their careers.

10th July 2017

Rein it in! 1,000 bogie saddles repaired for freight operator

In the rail industry, one of the most important aspects to maintaining high safety standard is regular inspection and maintenance of the rolling stock and tracks. For one freight operator this has included the overhaul of 250 coal wagons that needed new wear plates installing onto the bogie saddles, a task that Sulzer has completed as part of its on-going work in the rail sector. Keeping rail freight wagons in good running order requires the rolling stock to undergo general repairs every ten years or after a predetermined distance in work.

29th June 2017

Rotating equipment solutions on show at POWER-GEN Africa 2017

This year’s POWER-GEN Africa event is set to attract speakers and exhibitors from around the world to discuss the prominent issues of the industry and to present the latest innovations. At the show, repair specialist and pump manufacturer, Sulzer, will be highlighting specialist services to operators of gas turbines and other rotating equipment.

22nd June 2017

Running costs minimised in gas turbine power generation pumps

Traditionally designed to meet the specifications of a particular application without the need for speed control, large scale, high performance pumps now are undergoing some changes in operating conditions after the initial installation can result in a pump not operating near its best efficiency point (BEP), which makes the overall process less efficient.

12th June 2017

Rotating equipment expertise brought to EASA Convention 2017

Showcasing its global expertise in servicing rotating electromechanical equipment at the Electrical Apparatus Service Association (EASA) 2017 convention, Sulzer will be at the event taking place in Tampa, Florida. Taking place from 25th-27th June, attendees to the event can expect to network and discuss requirements with major players in the industry. Visitors will be able to talk with Sulzer experts on Stand 425.

9th June 2017

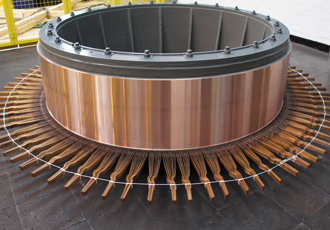

Generator fully refurbished in just 30 days

A key role in reducing the amount of waste that goes to landfill comes from waste-to-energy plants, as they are critical in the generation of power for the local grid. However, when a generator fails it is essential that repairs are completed quickly to get the plant back online. Sulzer was contracted to rewind a damaged generator and managed to return it to operation within just 30 days, minimising the costs associated with lost production.

1st June 2017

Improving reliability with outsourced maintenance strategy

Being a highly skilled operation, plant maintenance requires considerable resources for unexpected repairs and long term planning for preventative maintenance programmes. Large scale equipment, such as gas turbines, generators, compressors and large pumps, require specialist knowledge and expertise to maintain optimum performance. Increasingly plant owners are looking to outsource the major elements of equipment maintenance in order to improve reliability and minimise down-time.

30th May 2017

Maintenance expertise on offer at Seawork 2017

Returning to this year’s Seawork International exhibition Sulzer has a complete package of maintenance services that can be delivered through the company’s global network of service centres. Specialising in electrical and mechanical repairs, Sulzer offers expertise and high quality repairs for all sizes of marine vessel.

24th May 2017

Complete supply service offered for subsea ROV manufacturers

A considerable amount of expertise and design excellence is needed when manufacturing a hydraulic power unit (HPU) that is destined to operate on the ocean floor up to depths of 2,500m, in order to deliver reliable and sustained performance. Having provided the build and test service for some time, Sulzer has now taken on the procurement phase of the process to release the client from this time intensive task.

19th May 2017

Bringing precision engineering to DLR repair project

Sulzer has been contracted to inspect and repair the bogie frames of 76 rail vehicles over the next two years, as part of the ongoing maintenance and refurbishment project of the Docklands Light Railway (DLR). The project requires considerable attention to detail, especially with regard to the quality processes and documentation, as well as a streamlined welding and machining operation capable of completing each vehicle on time.

9th May 2017

Reverse engineering breathes new life into older pumps

Generally designed to perform long-term, some for decades even, large pumps have a valuable asset that requires periodic maintenance. When the performance of an older pump begins to deteriorate, it may be a sign that the impeller is worn or the volute has become corroded, and by the time this happens, finding new parts can be a considerable challenge. Fortunately, modern design techniques and manufacturing processes can create a vast range of components using reverse engineering.

5th May 2017