Sulzer Ltd

Address:

Zürcherstrasse 14

8401 Winterthur

Switzerland

8401 Winterthur

Switzerland

Sulzer Ltd articles

Displaying 81 - 93 of 93

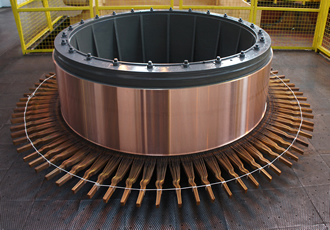

Large commutator refurbishment - a specialist operation

Several industries - including mining, steel, rail and power generation - rely on large motors equipped with commutators to produce the power required by their applications. However, without precision maintenance, these vital components can become inefficient and eventually fail. John Bird, Commutator Supervisor at Sulzer's Birmingham Service Centre looks at the processes involved in delivering a fully refurbished commutator.

4th June 2015

Re-engineered rotor improves performance for 4 MW refinery compressor

Large centrifugal impeller compressors are commonplace throughout the petrochemical sector, where they usually operate on a continuous duty basis. When a scheduled maintenance task at a refinery in Germany revealed the need for a new rotor assembly, working with specialists from Sulzer enabled the team responsible to improve the design and performance of the compressor without further interruption to service.

21st May 2015

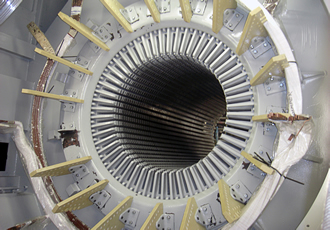

Generator repair keeps the lights on in Darwin

The power station in Darwin started life as a 200MW gas fired installation with three gas turbine generators that started full production in 1987. Having provided the population of Darwin with electricity for 25 years, it was important to ensure the generators continued to provide reliable service. This led to the owners calling on the services of Sulzer to carry out an overhaul of the generator including a rewind of the stator.

2nd April 2015

Generator repairs at sea ensure voyages are unaffected

As the trend for passenger ferries and cruise ships to increase in size continues, the requirement for reliable and effective back-up systems remains a constant. Modern vessels can deal with the failure of a generator without affecting passenger comfort, but completing the repair while remaining at sea requires a dedicated and skilled team of engineers.

17th February 2015

Rapid HV generator rotor repair saves oil refinery downtime costs

When regular maintenance checks on a high voltage 60MW generator at a large oil refinery signalled a potential earth fault in the rotor, engineers were keen to have a repair completed as soon as possible. The engineering manager contacted the leading specialists in this field, Sulzer, to carry out the repair and subsequent testing.

6th November 2014

Managing motor & generator repairs at nuclear power stations

In the nuclear energy industry more than most, safety is paramount and the design and specification used for equipment involved in nuclear generating plants are governed by a series of stringent regulations. The maintenance programs follow strict timetables with only certified contractors permitted to provide products and services, so when it comes to high voltage motors and generators, it is important to ensure that any repairs are going to make the grade.

26th September 2014

Psolid innovates plastics processing

The high optical clarity needed on products, especially for plastic injection moulding, requires using highly polished surfaces. Brush finishes are needed for plastics processing as well. It is a very time-consuming process with high costs to produce high gloss polished or brushed finished surfaces, so cost savings are absolutely essential.

23rd April 2012

Semiconductor Component Manufacturers Increase Lifecycle of Tools and Equipment with DLC Coat-ings of Sulzer Metco

Improved wear resistance, reduced particle generation and in-creased lifecycle are top priorities for manufacturers to optimise production process

Manufacturers can now reduce the friction and wear in all machinery used for producing semiconductor solutions and electronics thanks to market-leading Thin Film technology of Sulzer Metco. The wear-resistant, low-friction coatings increase the lifecycle of tools and machinery, enabling manufacturers to boost uptime, maintain productivity and maximise revenue.

12th January 2011

Sulzer Metco to Showcase Performance-Boosting Coatings Technologies at IMIS and PRI

Racing teams and automotive companies attending IMIS 2010 and PRI 2010 need only visit one stand for all their coatings needs after Sulzer Metco thin film coatings and Sulzer Metco SUMEBore confirmed their attendance at both exhibitions. The companies will share a booth so that delegates can discover the benefits of the companies’ complementary technologies. They can be found at Booth 433 at IMIS and Booth 3963 at PRI.

2nd November 2010

Sulzer Bolsters Product Portfolio to Create One-Stop Coatings Shop

Racing, automotive and engineering companies now have the convenience of getting all their coating solutions from a single supplier, thanks to Sulzer’s new broadened product portfolio. The company’s extended offering follows its takeover of Bekaert's DLC coating activities, which have now been fully integrated. The acquisition has established Sulzer as a one-stop shop for every customer’s coating needs.

7th October 2010

Sulzer to Showcase Extended Portfolio of Coating Applications for Racing and Automotive Markets at PMW Expo 2010 - Hall 7, Stand 7100

Racing teams and automotive companies can discover how to increase the durability of parts and components and boost their overall performance on Sulzer’s stand at Professional MotorSport World Expo 2010. The company recently acquired Bekaert's diamond-like carbon (DLC) coatings activities, establishing Sulzer as an expert one-stop coatings shop in the racing and automotive markets. PMW 2010 takes place 16 – 18 November 2010 in Cologne, Germany. Sulzer can be found in Hall 7, Stand 7100.

6th October 2010

Sulzer Acquires Diamond-like Carbon Coatings Activities from Bekaert

The DLC activities of Bekaert have been acquired by Sulzer Metco, a leading global supplier of services and products for surface solutions, covering thermal-spray and thin-film coating technologies. The acquisition, which includes Bekaert’s diamond-like carbon (DLC) coatings and racing activities, will deliver significant technological benefits to Sulzer and Bekaert customers, as both companies have a strong presence in complementary markets and produce complementary technologies.

20th August 2010