NSK UK Ltd

Address:

Northern Road

Newark

Notts

NG24 2JF

United Kingdom

Newark

Notts

NG24 2JF

United Kingdom

Phone: 01636 643031

NSK UK Ltd articles

Displaying 101 - 120 of 160

NSK releases new movie: Super Precision bearing manufacture at Newark UK factory

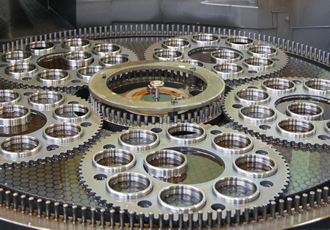

In order to meet market demands for higher speeds, reliability and individual product traceability, NSK has invested consistently in new materials and production techniques at its Newark UK manufacturing plant. NSK is proud to show customers its facilities and has released a virtual tour that provides viewers with a real insight into the production environment without coming to the plant.

7th October 2014

Bearing designs on display at Innotrans 2014

NSK will be exhibiting its latest bearing designs for traction motors, gearboxes and wheelsets drive units in Hall 21a, Stand 407 at Innotrans 2014. Innotrans is scheduled to take place in Berlin from 23rd to 26th September 2014, with the show expected to draw over 120,000 trade visitors.

27th August 2014

Technology Bearing Solutions Deliver Reduced Whole Life Costs In Food Processing And Beverage Sectors

Rolling bearings are key components in food and beverage processing machinery and equipment, their reliability and operating life having a significant effect in ensuring that operating costs are minimised. Moreover, as the pace of bearing technology accelerates, opportunities for technology transfer mean that bearings can play a wider role in reducing the whole life costs of food processing machines.

25th June 2013

Improving bearing life is key to reducing costs for cement plants

The working conditions of a cement plant do not foster long service life for machinery, due to dust, heat, moisture and vibration. Therefore it is essential that every opportunity is taken to improve the efficiency and reliability of the plant. Bearings are common to most pieces of equipment, so by concentrating on improving the service life of this critical component, significant savings can be made in maintenance and production costs. NSK Europe has developed several materials and technologies to improve bearing performance.

10th June 2013

€100m investment results in performance improvements for all deep groove ball bearings from NSK

Research and design innovation continue apace at NSK, where nearly 100 million Euros are invested each year in developing new technologies, lubricants, materials and surface engineering. For the most common form of rolling bearings, deep groove ball bearings, this has meant improved reliability even in extreme environments due to new seal technology, improved lubrication and greater operational efficiency.

3rd June 2013

Innovative Robustshot Angular Contact Bearings Employ Unique Lubrication System to Deliver Speeds in Excess of 3M dmn

NSK’s ROBUSTSHOT series high precision angular contact bearings are designed to satisfy the exacting demands of motorised machine tool spindles for smooth, reliable operation, rapid acceleration/deceleration, higher speeds – over 3million dmn - and longer life. The ROBUSTSHOT series meets the requirements of the global machine tool industry for ever increasing spindle speeds to enable a wider range of machining operations to be performed on a single machine tool.

18th April 2013

NSK Boosts Its Business in Emerging Markets

NSK announced today that it has established new branches in Saint Petersburg, Russia, and Dubai, United Arab Emirates, in the Middle East, both of which are important emerging markets. Business activities have begun to commence operations at both sites. Demand for bearings is projected to grow considerably in emerging countries as industries develop and infrastructure expands. Accordingly, NSK is adding these new branches and increasing its sales distributors in an effort to expand its sales areas and market share.

18th March 2013

NSK named supplier of the year by Franz Kessler GmbH

Franz Kessler GmbH based in Bad Buchau, Germany, has named NSK Deutschland GmbH its supplier of the year in the category of on-time delivery. Kessler is the largest European producer of motor spindles for the machine-tool industry and its components are often fitted with NSK’s high-speed bearings.

7th March 2013

NSK bearing solution achieves in excess of 1,000 hours use on concrete vibrators– 10x the life of other tested products

NSK has improved the competitiveness of an OEM manufacturer of concrete head vibrators, by providing a bearing substitution and lubrication programme that is delivering operating cost savings of €306 pa on each vibrator, plus improving operating life and reducing maintenance requirements, mainly for replacement bearings.

15th February 2013

NSK's Free Handy Pocket Guide Provides Best Practice Maintenance Data For SNN Series Plummer Blocks

NSK has a produced a handy pocket-sized guide for engineers, giving best practice maintenance information for the company’s SNN 500 and 600 series of plummer blocks. These units provide integrated bearing solutions - on shaft diameters from 20mm to 140mm - in demanding sectors such as general manufacturing, food processing, materials handling and agricultural.

7th February 2013

NSK Stainless Steel Spacea Bearings Solve Failure Problem Due to Bearing Contamination at Petrochemical Plant

NSK Spacea series bearings equipped with Molded Oil solid lubricant have solved a problem of premature bearing failures in the extremely demanding environment of a petrochemical plant in Spain. The bearings are installed on the submerged rollers of a conveyor belt and are directly in contact with water, hydrocarbons and particles in suspension from the production process.

22nd January 2013

Bespoke solutions for linear

Linear technology: bespoke solutions and green engineering are in demand. Ultra-steady running, a low noise level, high precision and ever-increasing outputs: these are the key trends in linear technology that NSK is catering for by developing new series of ball screws and linear guides. Green engineering is another important element of the development work. Customised versions are also developed regularly in response to clients’ increasingly specific demands.

6th December 2012

A small change with a big impact: Heat-resistant deep-groove ball bearings slash costs by approx. €115,000 p.a.

With its Asset Improvement Programme, NSK helps users of all kinds of machinery and equipment to find the ideal bearings for their application. Machine operators often seek NSK’s advice because they are experiencing specific problems – which is exactly what happened in the case of this particular food tin manufacturer.

28th November 2012

High-Performance Angular Bearings For Pumps

NSK’s recently introduced range of high performance angular contact bearings for industrial pumps has an optimised internal design that contributes significantly to lower running costs, allows downscaling of components, and saves energy by extending maintenance intervals. The optimised design delivers up to 50% more bearing life compared to standard angular contact bearings, and an improvement in basic dynamic load rating of approximately 13%.

2nd October 2012

New Free Industry Specific Brochure Shows Cement Producers How To Get More Bearing Life From Their Plants

NSK has published a new brochure outlining innovative bearing and material technologies to help operators of cement plants to get more operating life, improve efficiency and reduce maintenance costs under the most challenging operating conditions. Entitled ‘Bearings for the Cement Industry’, the new publication covers all areas of cement production - quarrying and extraction; crushing, grinding and blending; material preparation; pre-homogenisation, clinker grinding, conveying packing and shipping.

13th August 2012

NSK's Cost Saving AIP Programme Doubles Throughput for Cold Rolling Mill

NSK’s cost saving, asset improvement programme has doubled the amount of throughput a major international manufacturer of wire is achieving from a cold rolling mill, from around 500,000 tons to 1,000,000 tonnes, as result of solving a problem of bearing contamination with Water Tough WTF bearings.

31st July 2012

NSK Delivers Four-Times Bearing Life & Reduced Downtime Costs On Operation Of Sludge Press In Paper Recycling

A bearing customer in the paper recycling industry is benefiting from four- times bearing life and avoiding the considerable downtime and maintenance costs of partial shut every six-months, following the adoption of a bearing substitution solution for a sludge press developed by NSK as part of the company’s cost saving, asset improvement programme.

19th July 2012

NSK's Molded Oil Bearings Deliver Annual Cost Savings Of €10,560

A customer in the pulp and paper converting industry is benefiting from cost savings of €10.560 annually, plus improved productivity, longer bearing life and reduced maintenance, since replacing the existing bearings on a pulp converting machine with NSK’s unique Molded OilTM bearings.

12th July 2012

NSK and Brammer at Hillhead 2012 to provide interactive industry specific solutions to bearing problems

Global bearing manufacturer, NSK, is extending its customer-focussed activities at Hillhead 2012 by partnering with Brammer in the MRO supplier’s Mobile Centre of Excellence (stand A5) to provide industry- specific solutions to bearing problems experienced in the quarrying and mining industries.

2nd July 2012