NSK UK Ltd

Address:

Northern Road

Newark

Notts

NG24 2JF

United Kingdom

Newark

Notts

NG24 2JF

United Kingdom

Phone: 01636 643031

NSK UK Ltd articles

Displaying 81 - 100 of 160

NSK wheel bearing units save €58,000 in annual operating costs on a new stacker crane

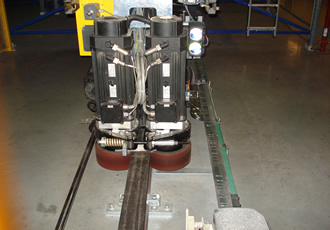

High availability is one of the primary criteria for stacker cranes deployed in automated storage and retrieval systems. Downtime due to breakdowns is unacceptable as material flow becomes interrupted, which in turn means production lines or customers (in the case of finished good warehouses) are left waiting for items.Drive unit of a rail-guided stacker crane

18th February 2016

High speed trains use high performance NSK bearings

Helping facilitate high speed train travel in Japan, NSK says that its high performance axle, motor and drive unit bearings have been selected for a prestigious new rail project. The bearings have been specified for the H5 rolling stock to be deployed on the Hokkaido Shinkansen high speed rail line being constructed between Shin-Aomori and Sapporo - the initial section of which is due to open in March 2016.Safety and reliability are paramount considerations on all rail projects, but especially on ultra-high speed trains where speeds of circa 320 kph (200 mph) are typical. With this in mind, nothing but the highest performance bearings will suffice.

1st December 2015

NSK Solutions App update adds even more value

NSK has updated its Solutions App to feature information that helps engineers understand the added value that can be achieved through the adoption of NSK bearings and associated services.NSK´s AIP - Added Value Programme, leads the industry in helping customers solve problems and save money as part of a straightforward step-by-step process that is made even easier to understand thanks to the updated Solutions App.

5th November 2015

NSK products make debut at Agritechnica 2015

Visitors to Agritechnica 2015 (Hanover, 10-14 November) will witness the debut appearance of NSK rolling bearings designed purposely for the agriculture industry. Central to the NSK exhibit will be ´Agri Disc Hubs´ - ready-to-install units deployed in soil tillage machinery such as compact disc harrows, seed drills and strip-till equipment.Agri Disc Hubs comprise double-row angular contact ball bearings that are able to absorb very high radial and axial loads. Via a flange, the units can be fitted directly and easily to disc harrows, for example.

30th September 2015

EMO MILANO 2015

NSK will feature many innovative products at EMO Milano 2015 (5-10 October), each offering specific advantages to forward-thinking builders of machine tools, automation systems and materials handling equipment.Visitors to stand B08 C07 (hall 9) will see for themselves why generations of machine tool designers have relied on the latest NSK technologies to ensure precise motion and control. Taking centre stage on the almost 100 m² stand will be a number of products making their exhibition debut, including ball screws, ball screw support bearings, angular contact ball bearings, cylindrical roller bearings, linear guides and seals.

10th September 2015

Building insulation production line is a cut above

Combating contamination in bearings is one of the single most effective ways to extend bearing life and consequentially to reduce the maintenance requirement of the machinery they are fitted to. When high quality band saw manufacturer Prosaw found that bearings were regularly failing on automated saws that had been supplied to a prominent manufacturer of building insulation, both Prosaw and the end user needed a solution quickly.

7th August 2015

NSK bearings deliver €96,000 saving for fish processor

Interrupting a continuous manufacturing process occasionally because of a bearing failure can be irritating, but when the failures become more frequent the costs in lost production start to mount up. For one large producer of fish products, repeated bearing failures on a heat exchanger unit demanded attention, which led to NSK delivering a huge annual saving through the installation of improved bearing technology.Scraped Surface Heat Exchanger (SSHE) systems are designed to operate as part of a continuous process where fouling of the heat exchanger and the subsequent reduction in heat transfer efficiency, can be expected. The internal scrapers perform two roles by removing the material build-up and also mixing the product at the same time.

30th July 2015

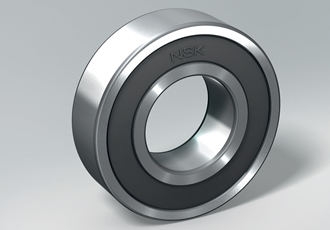

Expanded Range of NSKHPS High Performance Standard Bearings

The NSKHPS series of high performance standard bearings from NSK has been expanded in line with demand for reduced maintenance costs and more compact industrial machinery. Deep groove ball bearings, cylindrical roller bearings, high precision angular contact ball bearings and ball screw support angular contact thrust ball bearings have all been added to this increasingly popular series. NSKHPS bearings are able to extend service life significantly, and increase the limiting speed by up to 20%.In 2004 NSK introduced the first product in the NSKHPS series, a spherical roller bearing. The range was enhanced further in 2009, with the addition of angular contact ball bearings. With six types now available, circa 30,000 NSKHPS product variants are offered in total, giving machine builders an unprecedented choice for virtually any kind of modern machinery application.

28th July 2015

Split cylindrical roller bearings boost steel plant operations

Designed specifically to suit steel industry converters and continuous casting lines, optimised cylindrical roller bearings from NSK deliver benefits that include the use of up to 30% wider cylindrical rollers for accommodating greater loads. The bearings also provide longer replacement intervals, helping end users reduce downtime.

9th July 2015

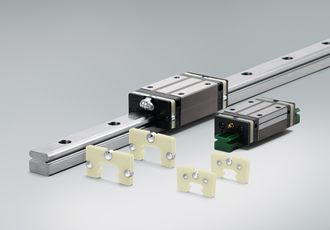

New NH and NS series linear guides from NSK offer 30% higher dynamic load rating

The demands that industry places on linear guides are becoming higher: they must be suitable for very fast applications, offer increased operational lifetime and cope with higher loads. The new precision UK manufactured NH and NS series linear guides from NSK satisfy all of these criteria, thereby enabling machine builders to either increase the performance of their products or to downsize.

6th May 2015

NSK low torque bearings improve energy efficiency in MRO sector

NSK is known across the world for its class leading reliability and long bearing life, as well as its economic and environmental credentials. Within the global automotive sector, NSK has worked with the industry to produce low torque bearings which help to reduce power consumption and emissions. Now these advances in engineering design are being applied to general purpose, deep groove ball bearings, which are used in a wide range of industrial applications.

17th March 2015

Interview with Michael Preinerstorfer, NSK Europe

In this interview, Michael Preinerstorfer – the new Managing Director of the European Industrial Business Unit (EIBU) and a qualified engineer – explains how he intends to further expand on the company’s good position with the help of his team. His aim is to offer users from the machine tool and plant construction industry superior added value with 100% in-house developments and extensive service.

12th March 2015

NSK bearings deliver €46k savings for steel plate rolling mill

A major steel manufacturer experiencing high maintenance costs relating to bearings on a plate rolling mill has improved the situation massively with an application specific product replacement from NSK. The existing open roll bearings required a daily maintenance routine to ensure sufficient lubrication before analysis by NSK led to a proposal or the installation of its Sealed-Clean™ range, which proved ideal for use in this heavily contaminated environment.

26th February 2015

Bakery saves €27,000 per year thanks to NSK bearings

NSK’s Molded-Oil technology has produced annual savings of more than €27,000 for a major food producer on the operation of the main make-up conveyor within a bakery. The producer was experiencing failures every 6 weeks with approximately 36 bearings being replaced every year, which was causing considerable downtime and lost production.

22nd January 2015

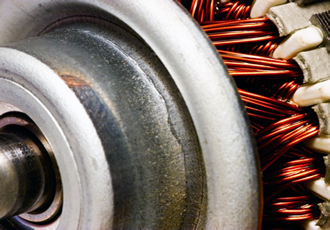

Bearing design for electric motors

As the development of more efficient electric motors continues to keep pace with upcoming regulations, it is important to ensure that all the components are engineered to the latest specifications, including the bearings. Tony Synnott, UK Engineering Manager for NSK Europe, explains how bearing design is affecting electric motor performance and reliability.

26th November 2014

Replace with Better - Quality replacement parts benefit end users

Reducing overall production costs and improving margins are the goals of most company managers. Using the right strategy is crucial and may include a number of initiatives that help to achieve the improved bottom line. Understanding the real cost of plant and equipment is a key requirement to improving both efficiency and reliability. NSK European Key Account Manager, Tim Cains, explains:

28th October 2014

NSK at Innotrans - Successful premiere in Berlin

At InnoTrans, the leading international trade fair for rail transport technology, NSK celebrated a premiere of the speedy sort. In Berlin, the company presented bearings for traction motors, gearboxes and wheelsets. The focus was on drives for trains that travel at speeds of over 200 km/h.

16th October 2014

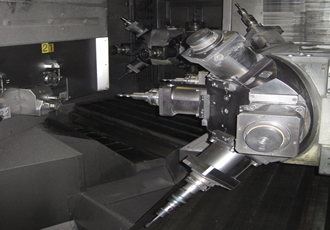

The AIP programme in machining

A car manufacturer was looking for a solution to prolong the service life of spindle bearings in their machining centres. Following a thorough analysis of the situation, the problem was solved by using sealed high-precision bearings: The service life of the bearings has now more than tripled.

14th October 2014