KOLLMORGEN Europe GmbH

Address:

Pempelfurtstraße 1

Ratingen

DE-40880

Germany

Ratingen

DE-40880

Germany

Phone: +49 2102 9394 0

Web: http://

KOLLMORGEN Europe GmbH articles

Displaying 1 - 20 of 59

New servo drive and motor package increases performance

Kollmorgen has released a new servo drive, motor and cable motion package, designed to increase machine performance and reduce footprint. The new Kollmorgen 2G Motion System, distributed by INMOCO and aimed at OEMs and system integrators, features integrated safe motion and is easy to install for existing and new machine designs.

23rd July 2020

Second generation of safety

SPS Nuremberg represents KOLLMORGEN as a sign of complete drive solutions, including for the growing demand for collaborative robots and automated guided vehicles. The AKM2G-series servo motors were therefore also expanded for applications in the low-voltage sector. Also a topic at the three-day automation trade fair: the second-generation functional safety technology, which has found its way into the AKD2G series servo inverters.

14th October 2019

Power-dense servo drive reduces wiring and filtering to save space

Kollmorgen has announced the new AKD2G Servo Drive, which is a dual-axis AKD2G, one of the most power-dense industrial servo drives on the market. . It substantially reduces mains wiring, fuses, and filtering to save significant panel space and cost. The AKD2G features expandable I/O (without increasing the size), removable memory, dual-channel STO, and the first drive-resident graphic display in the industry.

28th November 2018

The servo motors that help produce the robots

At the Hannover Messe trade show earlier this year, collaborative robots were a big feature. Small, intelligent, sensitive, and self-learning: The ways in which robots can be used are increasing all the time. And the level of acceptance is also rising - not least thanks to attractive prices and short ROI times. Off-the-shelf handling solutions are in demand and Yuanda Robotics has a range of market-ready robot systems.

19th June 2018

Clean cuts with linear motor and rotating blades

The new generation of the Topline series from KOLLMORGEN certainly shows off what the company has to offer when it comes down to its servo solutions and clean cuts with linear motor and rotating blades. Here Thomas Sautter, Sales Manager South, KOLLMORGEN, Ratingen explains more what the company has got on offer and how the products help its customers.

5th June 2018

Next-gen motion solutions for robotic applications at Robotics Summit

Visitors attending the 2018 Robotics Summit & Showcase, taking place 23-24th May in Boston, will see Kollmorgen who will be on booth #210 featuring its newest motion solutions for designers and manufacturers of commercial robotics and intelligent systems. Throughout the show, the company will offer exciting live demos and experts will be available to discuss real-world applications.

21st May 2018

Servo controller gets single-cable connection

Available in the UK through INMOCO of Daventry, the Kollmorgen S700 servo controller is now supplied with a single-cable motor connection, as are all Kollmorgen drives. The benefits of connecting drives using just one cable are obvious in machinery and plant construction: they include faster installation, space savings, reduced inertia, and lower costs to name but a few.

20th April 2018

Servo control now with easier integration

KOLLMORGEN expands single-cable connection technology to S700 servo drive range. The innovative single-cable technology is now available for its SERVOSTAR series S700 servo controllers. Available with full technical support in the UK from Heason Technology, the single motor feedback and power cable option - which is well proven on the AKD and AKD-N servo drive range - brings benefits which include faster, more straightforward and lower cost installation.

10th January 2018

Servo controller equipped with single-cable connection tech

The benefits of connecting drives using just one cable are obvious in machinery and plant construction: they include faster installation, space savings, reduced inertia, and lower costs to name a few. Following positive experiences with the AKD and AKD-N servo drives, KOLLMORGEN has now equipped the S700 with its single-cable connection technology.

8th January 2018

Shark teeth: Grinding wheel gets to work in minutes

In the metal processing industry, sintered tools have a reputation for being particularly hard-wearing and for maintaining their sharpness over a long period. However, processing saw blades, drills, and milling tools proves to be time-consuming as a result of their particular hardness. This is why the saw blade professionals from Alesa in Switzerland started their own development process to design a grinding machine for circular saw blades.

Author: Martin Rupf Bc. Sc., KOLLMORGEN

10th October 2017

Direct drives provide energy savings in coil handling

At the stainless-steel service centre Vogel-Bauer in the German town of Solingen, the new coil packaging system clearly demonstrates how effectively energy can be saved today. The lion’s share of efficiency gains of the systems built by Cologne-based machine builder KBD Engineering relates to the intelligent mechanics design together with the drive technology.

Author: Lars Kühn, Application Engineer, KOLLMORGEN

5th October 2017

Monitoring and controlling brakes crucial part of safety

KOLLMORGEN’s Product Manager for Safety Technology, Karl Pickan talks us through the safety technology at the company. Safety of people and machinery is a constant challenge, particularly with applications that involve loads transported and positioned vertically. There are challenging issues that arise from the design to the construction stages especially when the goal involves ensuring the safety of vertical axes with high loads using just the holding brake installed in the drive motor.

22nd September 2017

AKD2G servo drives to make a debut at PACK EXPO 2017

Kollmorgen will be exhibiting at this year’s Pack Expo from 25th-27th September in Las Vegas NV, and in addition to the company’s motion technology and latest product enhancements, visitors to the booth, C-1751, will be introduced to the new AKD2G servo drives. Kollmorgen set the industry standard in ease of use, performance, and flexibility with the first generation of AKD. Now Kollmorgen takes servo performance to the next level with the AKD2G.

5th September 2017

New generation of synchronous servo motors includes AKM2G

Exhibiting at this year’s Pack Expo, taking place from 25-27th September in Las Vegas, NV, Kollmorgen will be present at booth C-1751. The company plans to introduce a new generation of synchronous servo motors – the AKM2G. Kollmorgen applied decades of design and development experience to optimise the electromagnetic technology of the AKM2G.

4th September 2017

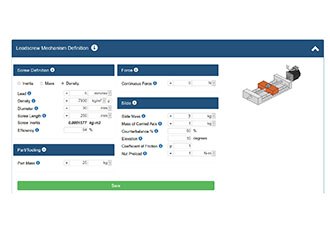

Motion control manufacturer provides digital customer experience

Designer and manufacturer of high performance motion control products, Kollmorgen, has recently launched a new catalogue of native CAD models built by CADENAS PARTsolutions. Kollmorgen was looking a boost to their digital customer experience, by providing an easy to use catalogue with which customers could design and download the exact product they need.

5th July 2017

It’s anything but trivial trying to fill cans with milk powder

The scaled technology and functioning interfaces are essential for Swiss Can Machinery I Hygienic drives from KOLLMORGEN. A solution for different applications and industries: the filling and packaging systems at Swiss Can Machinery AG shows how this objective can be achieved. The Swiss company turns to stainless steel motors for the actuators, for example when these systems are used for pharmaceutical products.

16th June 2017

.jpg)